GraphIC PCB electroplating process flow: Foil clad plate blanking, punching, drilling, reference hole, CNC drilling, inspection, deburring, chEMIcal plating, thin copper plating, thin copper inspection, brushing, film pasting (or screen printing), exposure, development (or curing), inspection, repair, graphic plating (Cu+Sn/Pb), film removal, etching, inspection, PCB repair, plug, nickel plating

1、 Graphic electroplating process flow

Foil clad plate → blanking → punching and drilling reference hole → CNC drilling → inspection → deburring → electroless thin copper plating → electroplating thin copper → inspection → brushing → film pasting (or screen printing) → exposure development (or curing) → inspection and repair → pattern electroplating (Cu + Sn/Pb) → Film removal → Etching → Inspection and repair → Nickel plating and gold plating of plug → Hot melt cleaning → Electrical on/off detection -->Cleaning treatment → Screen printing solder resistance figure → Curing → Screen printing MARK symbol → Curing → Shape processing → Cleaning and drying → Inspection → Packaging → Finished product.

In the process, the two processes of "thin electroless copper plating → thin copper plating" can be replaced by the one of "thick electroless copper plating", both of which have advantages and disadvantages. Pattern electroplating - etching method of double hole metallized plate is a typical process in the 1960s and 1970s. In the 1980s, bare copper clad PCB solder mask technology (SMOBC) was gradually developed, especially in the manufacturing of precision dual panel.

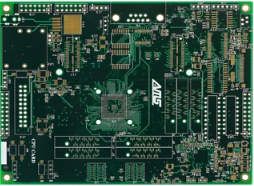

2、 SMOBC process

The main advantage of the SMOBC board is to solve the solder bridge short circuit between thin lines. At the same time, due to the constant lead tin ratio, it has better solderability and storage than the hot melt board. There are many methods to manufacture SMOBC board, including standard pattern electroplating subtraction method and lead tin stripping SMOBC process; Substitute tin plating or tin DIPping for the subtractive graphic electroplating SMOBC process of electroplating lead and tin; Plugging or masking hole method SMOBC process; Additive SMOBC process, etc.

The following mainly introduces the SMOBC process of pattern electroplating followed by lead and tin stripping and the SMOBC process of hole plugging.

1. L process method of pattern electroplating and lead tin stripping:

The SMOBC process of pattern electroplating and lead tin stripping is SIMilar to the pattern electroplating process. Changes occur only after etching.

Double sided copper clad foil → according to the graphic electroplating process to the etching process → lead and tin removal → inspection → cleaning → solder resistance figure → nickel plating and gold plating of plug → adhesive tape sticking of plug → hot air leveling → cleaning → screen printing marks and symbols → contour processing → cleaning and drying → finished product inspection → packaging → finished product.

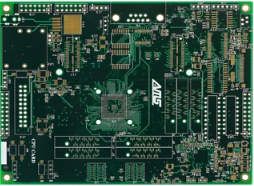

2. The main process flow of hole plugging method is as follows:

Double sided foil clad plate → drilling → electroless copper plating → whole plate copper plating → hole plugging → screen printing imaging (positive image) → etching → removing screen printing material and hole plugging material → cleaning → solder resistance pattern → nickel plating and gold plating of plug → adhesive tape pasting of plug → hot air leveling → the following process is the same as above to the finished product.

The process steps of this process are relatively simple, and the key is to block holes and clean the ink that blocks holes.

In the hole blocking process, if a special masking type dry film is used to cover the holes instead of using the hole blocking ink to block the holes and screen printing imaging, and then the holes are exposed to make positive images, this is the mask hole process. Compared with the hole plugging method, it no longer has the problem of cleaning the ink in the hole, but has higher requirements for masking the dry film.

The foundation of the SMOBC process is to first produce bare copper hole metallized double-sided boards, and then apply the hot air leveling PCB process.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱