WhICh parts of the cleaning free process of FPC patch are most likely to fail?

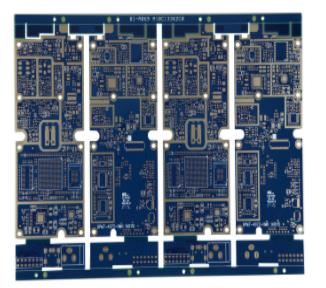

PCB manufacturers, PCB designers and PCBA manufacturers explain to you the cleaning free process of FPC pastes and which parts of industrial circuit boards are most likely to fail?

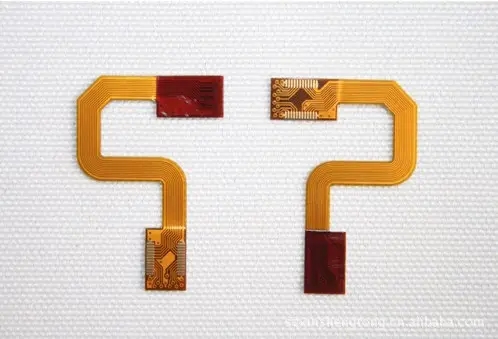

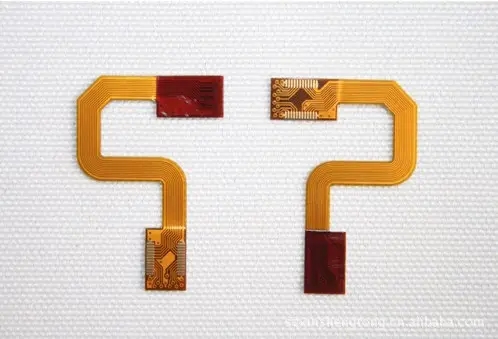

Cleaning free FPC pastes after processing is a systematic project, and man-made pollution caused in the production process should be avoided as far as possible. What are the cleaning free process control measures for FPC mounting?

The cleaning free process must ensure that the FPC and components meet the required cleaning standards before assembly; Ensure that the flux and solder paste meet the quality requirements of cleaning free; Avoid pollution in each process of manufacturing; If necessary, use nitrogen to protect welding.

1. When purchasing qualified components, do not open the seaLED package in advance. Before assembly, check the cleanness of FPC and components, and check whether they are affected with moisture. If necessary, clean and dry them.

2. During the operation of printing solder paste and SMT patch, direct hand contact should be avoided to prevent hand sweat, fingerprints, etc. from polluting FPC.

3. In wave soldering process, low solid content and weak organic acid type flux shall be used, and ammonia gas shall be used for protection during welding. The spray coating method is used for the flux. On the prEMIse of ensuring the welding quality, the coating amount of the flux shall be reduced as far as possible to minimize the residual amount of the flux after welding.

4. For flexible circuit board (FPC) SMD circuit boards in general electronic products, medium activity and low residual rosin flux can be selected. The application of flux shall be of spray type and ultrasonic spray type as far as possible to control the flux dosage.

5. Regularly check the composition and impurity content of solder alloy in wave soldering tin pot, and replace it if it does not meet the requirements.

6. The opening of the cleaning free solder paste printing template is reduced by 5% to improve the printing accuracy and prevent the solder paste from being printed outside the pad.

7. Generally, recycled solder paste cannot be used.

8. Reflow soldering shall be completed within 4 hours after printing.

9. The real-time temperature curve must be measured before production to make it meet the process requirements.

10. After manual repair welding and repair, the flux that flows out of the solder joint and is not heated shall be wiped off immediately.

Which parts of the industrial circuit board are most likely to fail?

Industrial circuit boards often need to be repaired, and the vulnerable parts on the circuit board should be understood during maintenance. So, which parts of the industrial circuit board are most likely to fail?

l. The place with unreasonable design is most likely to fail

First, the heat dissipation problem. Many circuit boards are damaged because of poor heat dissipation design; Secondly, the copper foil wire of the circuit board is too thin, which is very easy to be burnt out due to overcurrent, making the motherboard unable to work.

2. Frequently used places are prone to failure

For example, the drive motor of the circuit board, the rotating shaft, the switch tube of the switching power supply, and the common keys of the operation panel.

3. Components with heavy load, high power and high working voltage are most likely to fail

The power supply, drive circuit, power control devices and other components of the circuit board are generally close to the heat sink. If the protection measures are not enough and the heat dissipation is not good, it is easy to become the first place where the failure occurs.

4. The protection circuit is most easily damaged

The valuable chips or components on the circuit board are equipped with protective equipment. Once the circuit board is abnormal, the first problem is these protective circuits.

5. The interface and flat wire of the inner connecting base and connector are easy to be poorly contacted or broken

Such as poor contact between board and slot, poor contact between wire plug and terminal block, and faulty soldering of components. PCB manufacturers, PCB designers and PCBA manufacturers explain to you the cleaning free process of FPC pastes and which parts of industrial circuit boards are most likely to fail?

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱