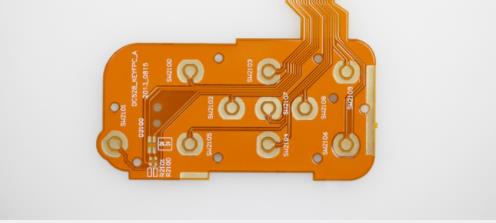

Introduction to the method of drying and dehumidifying soft circuit boards

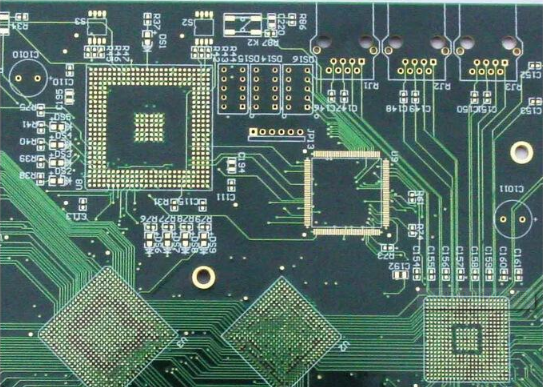

PCB manufacturers, PCB designers and PCBA manufacturers will explain the drying and moisture removal methods of flexible PCB

Can the bare soft plate be taken out of the oven immediately after being drained of moisture by drying at 150 ℃? no way! The temperature must be lowered slowly, and can only be taken out after the temperature drops below 60 ℃! This is because, after the soft board is baked at high temperature, especially when the baking temperature is close to or more than the glass transition temperature (Tg) of the base material, the resin in the base material is in a highly flexible and elastIC state. At this time, if rapid cooling is adopted, the cooling speed experienced by the epoxy glass cloth insulating base materials with and without copper foil circuit (or circuit inside the board core) will be significantly different. This difference in cooling rate will cause the resin that has been softened in the baking process to have different cooling and hardening rates in the parts with and without copper foil, thus forming local stress. The greater the temperature difference between the oven temperature and the room temperature during the plate taking operation, the greater the stress caused by the difference in cooling speed, and the more serious the consequences of the plate surface warping!

There was once a company in which the production department treated the soft plates that had been stored for an extended period with a 150 ℃ temperature before welding, and some of the plates were warped. When analyzing the cause, there was a disagreement with the incoming inspection. I suggest that they take the boards of the same type, thickness, SIMilar size, storage conditions and time from the stock, and then use the 150 ℃ temperature condition to conduct the wet drying before welding again, and then immediately take them out of the oven and place them on the platform with the room temperature of about 27 ℃. After the board is completely cooLED, the board warping fault can reappear.

The moisture removal of the soft plate needs to adopt the ladder type slow temperature rise (gradient temperature rise), rather than rapid temperature rise. This is not only to comply with the release characteristics of epoxy resin to water molecules, but also to avoid the warping of soft board caused by rapid temperature rise. Similarly, after the drying and moisture removal, the cooling of the plate must also be slow (gradient cooling) to avoid local stress in the soft plate substrate caused by "rapid cooling", which will lead to the warping of the plate.

As far as moisture elimination is concerned, we do not propose to raise the temperature of the drying plate to the glass transition temperature (Tg) of the substrate or above 125 ℃, unless it is necessary to remove the residual stress in the plate at the same time during moisture removal.

In general, the temperature of the stress relief baking plate must be raised to the Tg temperature of the substrate (such as epoxy glass cloth laminate) plus more than 20 ℃, and the operation specifications of gradient temperature rise (with constant temperature platform) and slope (℃/min) temperature drop (no constant temperature platform is required) must be strictly implemented. If the board is slightly warped, it needs to be leveled in the process of stress relief and drying, and the board must also be placed horizontally and pressurized, or pressed with clamping tooling. Obviously, the "stress relief" drying plate also completes the "moisture removal" drying plate at the same time.

Generally, we call the printed board substrate with Tg ≤ 130 ℃ as low Tg board; The printed board substrate with Tg=150 ℃± 20 ℃ is called medium Tg board; The printed board substrate with Tg ≥ 170 ℃ is called high Tg board.

No matter what type of printed board with Tg value, under its Tg temperature, because the base material epoxy resin always maintains a hard and rigid state, the probability of forming local internal stress during cooling is very low, and the probability of warping of the board is also very low. PCB manufacturers, PCB designers and PCBA manufacturers will introduce the drying and moisture removal methods of flexible PCB.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱