Analysis of PCBA process flow and terminology learning

Usually, the word PCBA is often heard in English about SMT industry Today, I will learn related terms and PCBA production to deal with with you

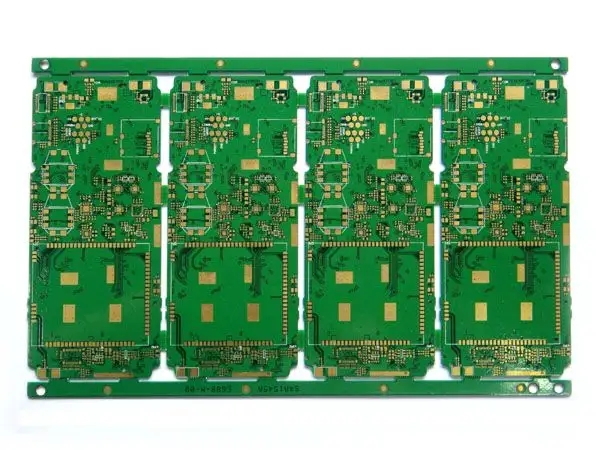

PCBA is the abbreviation of printed circuit board+component. In short, the whole process of empty PCB assembly through SMT and then through DIP is calLED PCBA. In layman's terms, a PCB is a circuit board without upper components, while a PCBA is a circuit board with soldered electronIC components.

PCBA process is the combination of SMT process and DIP process. According to the requirements of different production processes, it can be divided into single-sided patch mounting process, single-sided dip packaging process, single-sided mixed packaging process, single-sided patch mounting and insertion mixing process, double-sided patch mounting process and double-sided mixed process installation process. PCBA process involves carrier plate, printing, wiring, reflow soldering, soldering, wave soldering, testing and quality inspection. See PCBA process flow chart below for details.

Circuit board

Brief analysis of PCBA production process and terminology learning

Different types of PCB have many different processes. The following is a brief description of each situation. SIMple processing of PCBA:

1. PCBA processing single-sided patch: solder paste printing patch reflow. Add the solder paste to the component pad. After the solder paste printing of the bare PCB is completed, install the related electronIC components through reflow soldering, and then perform reflow soldering.

2. PCBA processing double-sided pastes: A-side printing solder paste pastes reflow soldering flip B-side printing solder paste pastes reflow soldering. In order to ensure the aesthetics and functionality of PCB, some PCB design engineers will adopt the double-sided installation method. IC components are arranged on side A and chip components are instalLED on side B. Make full use of PCB board space and minimize PCB board area.

3. PCBA processing single side mixed assembly (SMD and THC are on the same side): solder paste printing paster reflow soldering manual parts (THC) - wave soldering;

4. Single side mixing (SMD and THC are on both sides of the PCB): B-side printing red adhesive patch red adhesive curing - slap-A side welding piece - B-side wave soldering;

5. Double side mixing device (THC has A-side pastes, A-side pastes and B-side pastes): A-side printing solder paste - pastes reflow soldering flip plate B-side printing red glue - pastes red glue curing flip plate A-side solder pieces B-side wave soldering;

6. Double sided mixed packaging (SMD and THC on both sides of A and B): A side printed solder paste - paster reflow soldering flip plate B side printed red adhesive - paster red adhesive curing flip plate A surface sealing piece B side wave soldering B side sealing piece. The following two methods are mixed on both sides. The first method is to heat the PCBA module for three tiMES, which is inefficient. The wave soldering pass rate using the red glue process is low. This is not recommended. The second method is applicable to the case where there are more double-sided SMD components and fewer THT components. Manual welding is recommended. If there are many THT components, wave soldering is recommended.

In the welding process, the SMAllest variables should belong to machinery and equipment, and they should be checked first. In order to achieve the correctness of the check, independent electronic equipment can be used for assistance, such as using a thermometer to detect various temperatures, and using an electricity meter to accurately calibrate machine parameters.

PCBA is processing the empty PCB through a process, and finally processing it into electronic products that can be used by users In the production process, each link has a link, and which link has a quality problem will have a great impact on the product quality

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

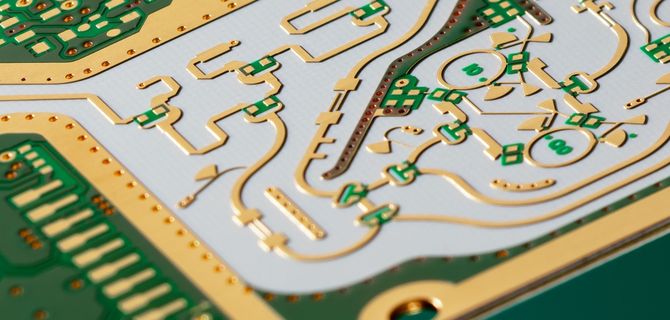

High Frequency Circuit Board and SMT chip are waiting for your presence again.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱