Common problems and solutions of dispensing in SMT process

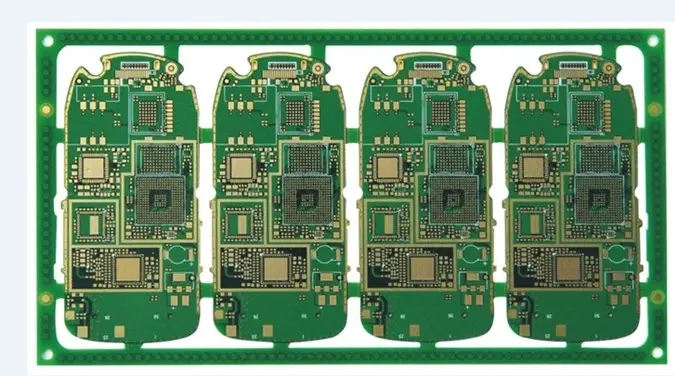

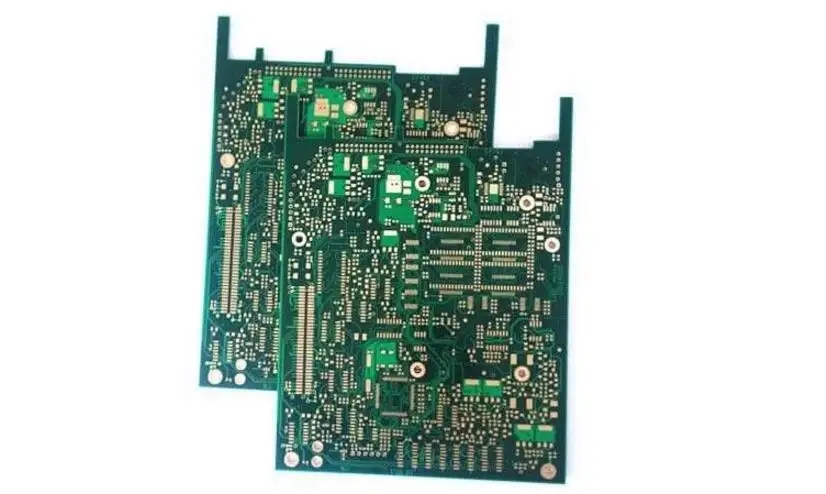

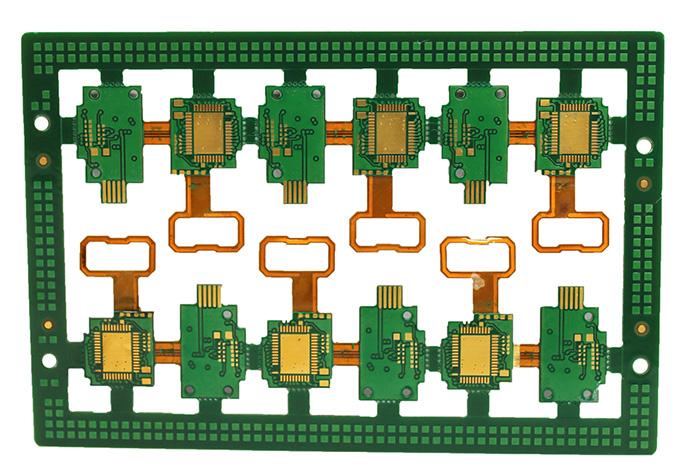

The Circuit board manufacturer and circuit board designer will explain the common problems and solutions in dispensing during SMT manufacturing

Problems in dispensing and solutions

The dispensing process in SMT processing is mainly used for the through hole insertion (THT) and surface mount (SMT) coexistence of lead components. At the same time, there will be a lot of problems. Below we will list the main problems and solutions.

Problems and solutions

1. Drawing and trailing

SometiMES, the process parameters of the dispenser equipment are not adjusted properly, whICh may lead to wire drawing tailing. Wire drawing trailing refers to the generation of thin lines or tails at the top of the glue point, which may collapse and pollute the bonding pad, causing false soldering. To solve this problem, we can heat on or near the glue dripping tip to reduce the viscosity, so that the glue filament of the patch can be easily disconnected. It can also reduce dispensing pressure and adjust needle height;

2. Satellite point

Satellite dots are SMAll and irrelevant glue dots generated during high-speed dispensing. At this time, we should often check whether the needle is damaged and adjust the height of the injection head and PCB.

3. Popcorn, hole

Popcorn and cavities are caused by air or moist gas entering the patch adhesive and suddenly bursting out during curing to form cavities. This will cause the PCB board to bridge or short circuit. Low temperature curing can be used to solve this problem. The heating time is extended, and the time of patch and curing is shortened.

4. Empty or less glue

In the dispensing process, if bubbles are mixed in the patch adhesive, the needle is blocked or the air pressure of the production line is low, there will be empty play or less glue output. Therefore, we should always replace the cleaning needle and adjust the machine pressure appropriately.

5. Discontinuous glue spots

The reason for discontinuous glue spots: the thimble of the needle falls on the bonding pad. You can use a different needle to solve this problem. It may also be that with the decrease of the glue level, the pressure time is not enough to complete the glue dripping cycle. This problem can be solved by increasing the pressure and cycle time.

6. Element displacement

Too much or too little glue, low viscosity, and too long PCB placement after dispensing will cause component displacement. Check whether the mounting height is appropriate, and the PCB shall not be placed for more than 4h after dispensing.

7. Cure, component peeling after wave soldering

If the curing temperature is low, the amount of glue is not enough, and the components or PCB are polluted, the chips will fall off. At this time, PCB curing curve should be adjusted to check whether components or PCBs are contaminated.

8. After curing, the element pin floats or displaces

After curing, the component pin will float, and the solder will enter the bonding pad after wave soldering. In severe cases, short circuit and open circuit will occur. The main reason is that the mounting adhesive is too much, and the components are displaced when mounting. The solution is to adjust the dispensing process parameters, control the dispensing amount, and adjust the patch process parameters so that the mounting components do not shift.

There will be many problems in the SMT process. Here are just a few examples and solutions. However, we still need to consider and refer to the actual situation in order to solve the problems efficiently.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱