Four "Ways" Must Be Followed in Repairing Strange Circuit Boards

The Circuit board manufacturer and circuit board designer explain the four "ways" that must be followed for circuit board maintenance

When a relatively unfamiliar circuit board needs to be repaired without any schematIC diagram, the so-calLED "experience" in the past is difficult to achieve. Although people with profound hardware skills are confident in the repair, if the method is not correct, it will still work with twice the effort. So, how can we improve the maintenance efficiency? According to the statistics of our imported equipment maintenance center, the following steps should be followed in an orderly manner.

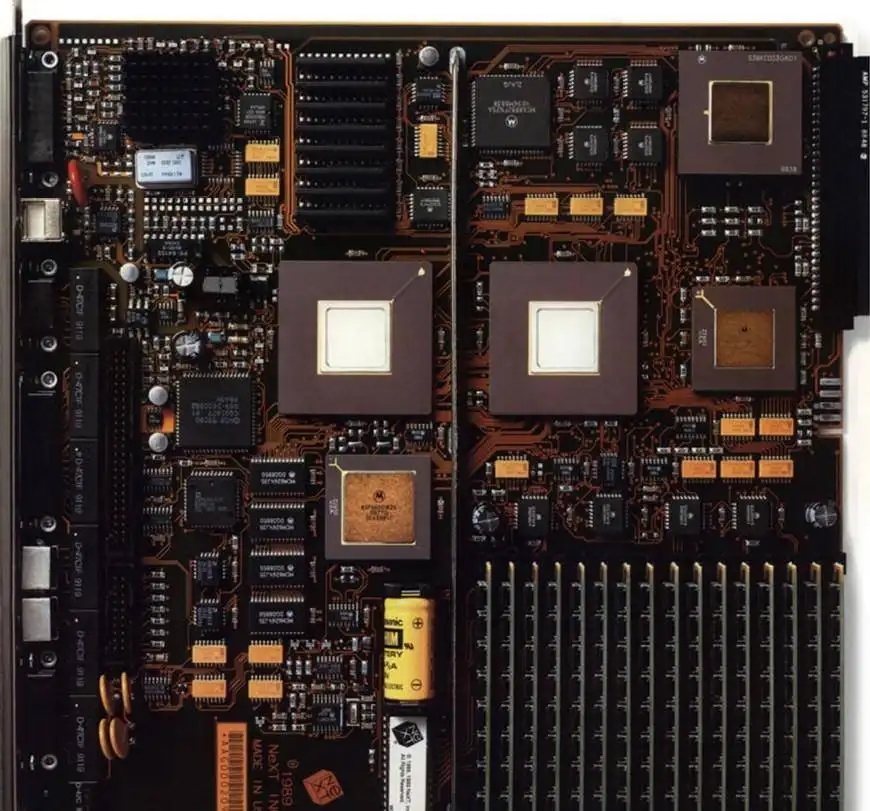

Method 1: First look, then measure

Tools: multimeter, magnifying glass

When holding a circuit board to be repaired, it is a good habit to first visually inspect it, and if necessary, use a magnifying glass to see what?

Mainly:

1. Whether there is broken wire;

2. The force components such as resistance, electrolytic capacitor, inductor, diode and triode are disconnected;

3. Whether the connecting wire of the printed board on the circuit board is broken or stuck;

4. Has anyone repaired it? Which components have been moved? Whether there are mistakes in operation such as false welding, missing welding and inverted insertion;

After confirming that there is no above condition, first use a multimeter to measure the resistance between the power supply and the ground of the circuit board. Usually, the resistance of the circuit board is 70-80? Above, if the resistance value is too SMAll, only a few or ten ohms, it means that there are components on the circuit board that have been broken down or partially broken down, and measures must be taken to find out the components that have been broken down. The specific method is to supply power to the board to be repaired, touch the temperature of each component on the circuit board with your hand, and the hot lecturer will focus on the suspect. If the resistance value is normal, use a multimeter to measure the resistance, diode, triode, field effect transistor, section switch and other force components on the board. The purpose is to first ensure that the measured components are normal. Our reason is that problems that can be solved with a multimeter should not be complicated.

Method 2: Outside before inside

Tool: circuit online maintenance instrument

If circumstances permit, it is better to find a good board as the same as the board to be repaired as a reference, and then use the dual rod VI curve scanning function to perform a good and bad comparison test on the two boards. The initial comparison point can start from the port, and then go from the outside to the inside, especially the capacitance comparison test, which can make up for the defect that it is difficult for the multimeter to detect whether there is leakage online.

Method 3: easy before difficult

Tools: circuit online maintenance instrument, electric soldering iron, MARKing pen

In order to improve the test effect, before the online function test of the circuit board, some technical treatment should be done to the board to be repaired to minimize the negative impact of various interferences on the test process. The specific measures are:

1. Preparation before test

Short circuit the crystal oscillator, and weld the next leg of the large electrolytic capacitor to open it, because the charging and discharging of the capacitor can also cause interference.

2. Use exclusion method to test the device

During the online test or comparison of devices, please directly confirm the test results of devices that pass the test (or are relatively normal) for recording; If the test fails (or the comparison is out of tolerance), it can be tested again. If it still fails, the test results can be confirmed first, and the test continues until the devices on the board are tested (or compared), and then go back to deal with those devices that fail (or the comparison is out of tolerance). The instrument also provides an informal but practical processing method for devices that fail to pass the function online test. Because the power supply of the instrument to the circuit board can be applied to the corresponding power supply and grounding pin of the device through the test clip, if the power pin of the device is cut, the device will be separated from the circuit board power supply system, and then the device will be subject to online function test, As other components on the circuit board will no longer interfere, the actual test effect is equivalent to "quasi offline", and the accuracy rate will be greatly improved.

3. Use ASA-VI curve scanning test to compare devices not covered in the test library

As ASA-VI intelligent curve scanning technology can be applied to the comparative test of any device, as long as the test clamp can clamp the device, and there is a reference plate, through the comparative test, the device also has strong fault detection capability. This function makes up for the deficiency that the device online function test is restricted by the test library, and expands the detection range of the instrument to the circuit board fault. In reality, it is often impossible to find a good board as a reference, and the circuit structure of the board to be repaired does not have any symmetry. In this case, the ASA-VI curve scanning comparison test function does not work, while the online function test cannot complete the test of every component on the circuit board due to the incomplete component test library, and the circuit board still cannot be repaired. This is the limitation of the circuit online maintenance instrument, Just like there is no medicine that can cure all diseases.

Method 4: Static before dynamic

At present, the circuit online maintenance instrument can only perform functional online testing and static characteristic analysis on the components on the circuit board. Whether the circuit is completely repaired must be tested and verified by the whole machine. Therefore, it is better to check whether the power supply of the equipment is correctly supplied to the circuit board as required during the inspection.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱