The components are easy to fall off after the gold plate is welded

Problem description:

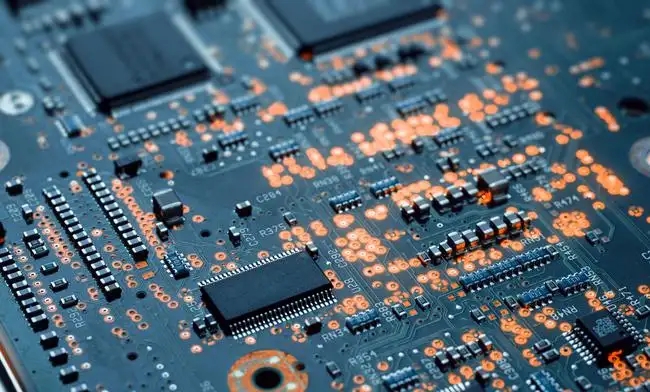

After the customer has welded our company's gold plate, the welded components are very easy to fall off. We paid great attention to it. We checked the production records of this batch at that time, found out the empty boards of this batch of circuit boards in stock, and sent them to the tin spraying factory for tin spraying to test the tin coating effect of the board. At the same time, we sent the empty boards to the patch factory for lead and lead-free patch experiments, and tested their actual patch effects. No problems were found. The customer sent back the problem board in kind, and we checked it. It is true that the devICe is very easy to fall off. Look at the shedding point, there is a layer of dumb black substance.

As this undesirable phenomenon involves many processes such as the surface treatment of circuit boards, solder paste, reflow soldering and SMT surface mounting process, in order to find out the cause accurately, we convened the foundering plant, the mounting plant, the solder paste plant and the process department of our company to study what the problem is.

Cause analysis:

We found this circuit board produced in the same batch in stock. Do analytical experiments to find out where the problem lies:

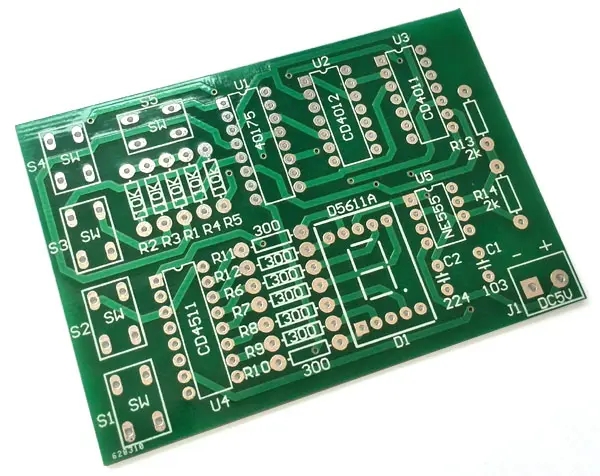

1: Analysis of the problem board's gold section:

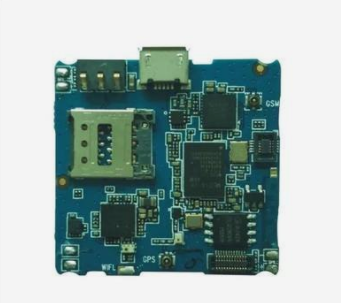

2: The stock boards shall be returned to the tin spraying factory for tin spraying, and the solderability of the gold deposit on the circuit board shall be tested.

3: Solder paste is brushed on the boards in stock, reflow soldering is conducted, and the actual solderability of circuit boards is tested.

4: Slice analysis of the solder joint of the circuit board returned by the customer.

5: Remedial measures for circuit boards returned by customers.

PCB welding test

Through a series of experimental analysis and judgment, a nickel layer is plated on the copper foil surface of the circuit board, and then a layer of gold is deposited on the nickel layer to protect the nickel layer from oxidation. During patch welding, first apply a layer of solder paste on the bonding pad. The solder paste naturally penetrates through the gold deposit layer and contacts the nickel layer (the dull black is the result of the action of the solder paste and the nickel layer). The solder paste contains some active ingredients. When the temperature reaches the melting temperature of the solder paste during reflow soldering, with the help of the active ingredients, the tin and each layer form a metal bonding layer (IMC).

The boards returned by customers did not meet the conditions required for welding, such as the temperature of reflow soldering (low temperature in the north, insufficient preheating, and the actual temperature is inconsistent with the temperature zone table), the activity of solder paste (storage conditions of solder paste), the thickness of steel MESh, etc., which resulted in the failure of nickel layer to form a metallized layer with tin, resulting in the device falling off.

It is a pity that:

A: The first board production inspection was not carried out during the production of batch boards. It was very troublesome to find problems after all the boards were completed.

B: The active ingredients contained in the solder paste are effective and volatilized when the first reflow soldering is conducted at high temperature, and no effective alloy layer is formed. The effect is not obvious when the solder paste is welded at high temperature again, which is unfavorable for remediation.

Interim Remedies:

As it is batch plate, manual electric soldering iron repair welding and manual repair welding with hot air gun do not have practical operability. So although it is useful, it cannot solve the problem.

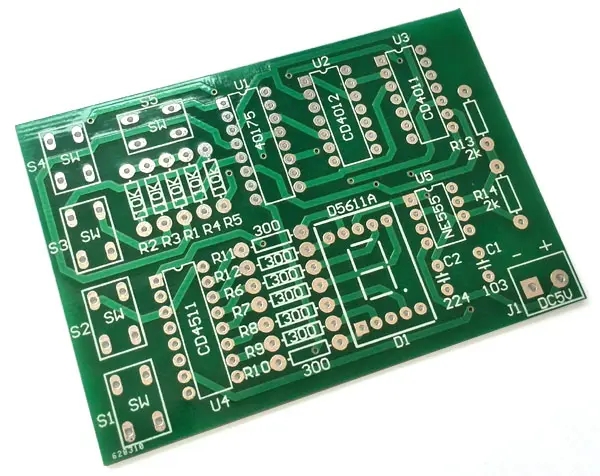

Raise the furnace temperature and reflow soldering again. Although the help of the active component of solder paste resistance is lost, the metal bonding layer can also be formed under sufficient high temperature. As for the effect and high temperature loss, we need to ask the customer to make a balance.

We tested that,

The problem board returned by the customer was reflowed at 265 degrees, and the display still fell off.

Adjust the reflow temperature to 285 ℃, and then reflow again. As a result, the display will still fall off.

Increase the reflow soldering temperature to 300 ℃ again, and then reflow soldering again, resulting in firm welding.

Will the effect of repairing the problem board with flux be better? If the customer needs, we can arrange the patch factory to do the test again.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱