Selection of solid flux volume

Flux: a chEMIcal substance that can help and promote the welding process in the welding process, and has a protective effect and prevents oxidation reaction. Flux can be divided into solid, liquid and gas. It mainly includes "auxiliary heat conduction", "removing oxides", "reducing the surface tension of the welded material", "removing the oil stain on the surface of the welded material, increasing the welding area", and "preventing reoxidation". The two key roles in these aspects are "removing oxides" and "reducing the surface tension of the welded material".

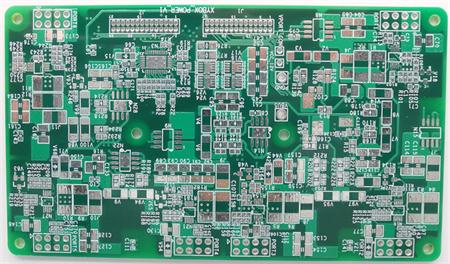

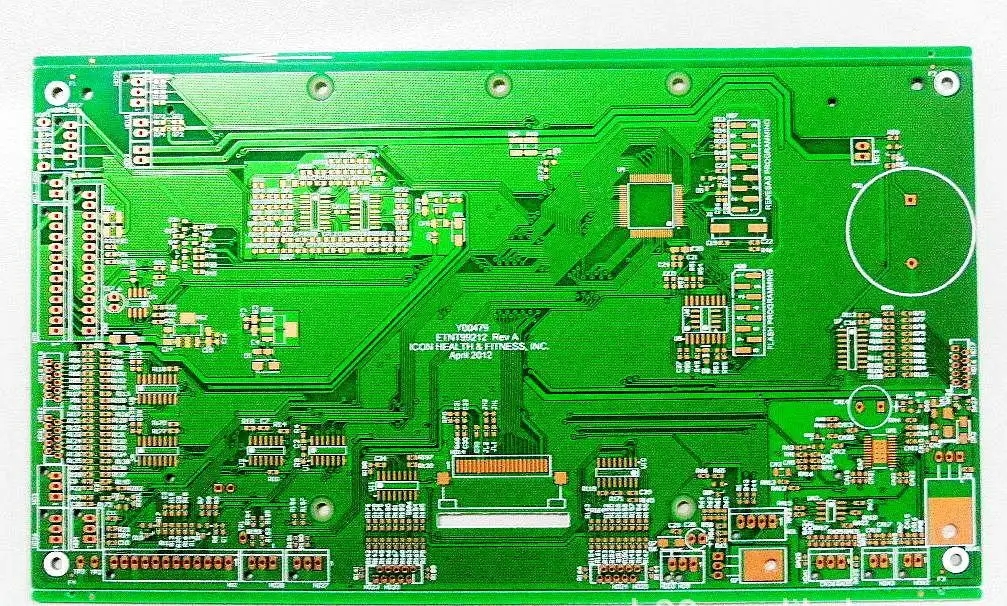

In PCBA processing, many engineers are trying to control the amount of flux used. However, in order to obtain good welding performance, more flux is sometiMES required. In the selective welding process of PCBA processing, engineers tend to focus only on the welding results and not on the flux residue. Most flux systems use a glue drip devICe.

In pcba processing, many engineers are trying to control the amount of flux used. However, in order to obtain good welding performance, more flux is sometimes required. In the selective welding process of PCBA processing, engineers tend to focus only on the welding results and not on the flux residue.

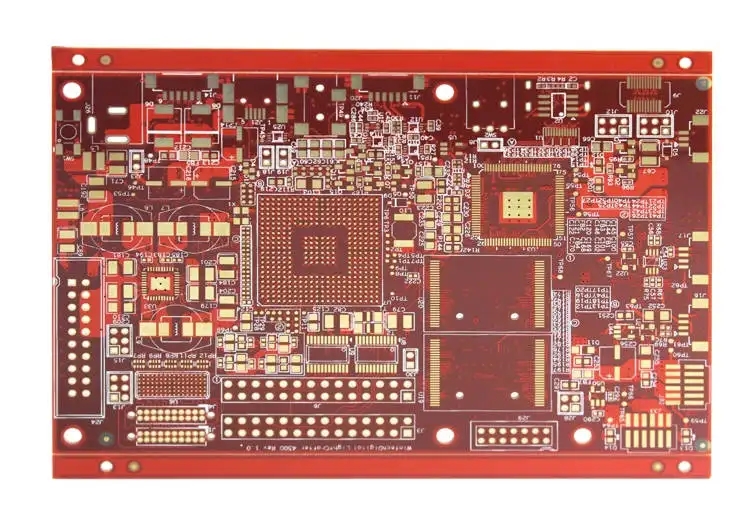

Selection of solid flux volume in PCBA product processing

Most flux systems use a glue drip device. In order to avoid reliability risk, the flux selected for selective welding should be inert - that is, inactive - when it is in an inactive state.

Applying more flux will lead to the potential risk of penetration into the SMD area and residues. Some important parameters in the welding process will affect the reliability. The most critical is that the inactive part is formed when the flux penetrates into SMD or other processes at a lower temperature. Although it may not have a bad effect on the final welding effect in the process, when the product is used, the combination of the inactive flux part and the humidity will produce electromigration, making the expansion performance of the flux a key parameter.

A new development trend of using flux in selective welding is to increase the solid content of the flux, so that the welding with higher solid content can be formed as long as a SMAll amount of flux is applied. Generally, 500-2000 is required for welding process μ G/in2 of solid flux. Except that the flux can be controlLED by adjusting the parameters of the welding equipment, the actual situation may be more complicated. The expansion performance of the flux is critical to its reliability, because the total amount of solid after the flux is dried will affect the welding quality.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱