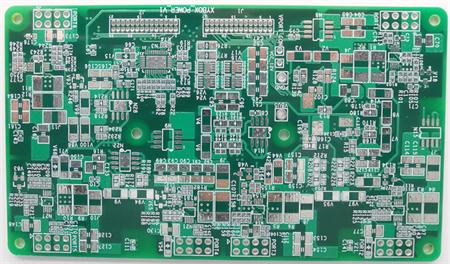

Here are some of the most frequently encountered PCB problems and how to identify them. In case of PCB laminate problem, it should be considered to add it to PCB laminate material specifICation. How to solve the problem of PCB copper clad laminate?

1、 To be able to search

It is impossible to manufacture any number of PCB without encountering some problems, which is mainly attributed to the material of PCB copper clad laminate. When quality problems occur in the actual manufacturing process, it seems that PCB substrate materials are often the cause of problems. Even a carefully written and practically implemented technical specification for PCB laminates does not specify the test items that must be carried out to determine that PCB laminates are the cause of production process problems. Here are some of the most frequently encountered PCB laminate problems and how to identify them.

In case of PCB laminate problem, it should be considered to add it to PCB laminate material specification. Generally, if this kind of technical specification is not enriched, it will cause continuous quality changes, and then lead to product scrapping. Generally, the material problems caused by the quality change of PCB laminates occur in the products manufactured by manufacturers with different batches of raw materials or with different pressing loads. Few users can hold a large number of sufficient records to enable them to distinguish specific pressing loads or material batches at the processing site. As a result, it often happens that PCB is continuously produced and instalLED with components, and warping is continuously generated in the solder tank, thus wasting a lot of labor and expensive components. If the loading batch number is immediately available, the PCB laminate manufacturer can check the resin batch number, copper foil batch number, curing cycle, etc. That is, if the user cannot provide continuity with the quality control system of the PCB laminate manufacturer, the user will suffer long-term losses. General problems related to substrate materials during PCB manufacturing are described below.

2、 Superficial problems

Symptoms: poor adhesion of printing materials, poor adhesion of coating, some parts cannot be etched, and some parts cannot be soldered.

The inspection method that can be used is usually visual inspection by forming visible water MARKs on the plate surface:

Possible causes:

Because of the very dense and smooth surface caused by the demoulding film, the uncoated copper surface is too bright.

Generally, on the uncoated side of the laminate, the laminate manufacturer does not remove the release agent.

Pinholes on the copper foil cause resin to flow out and accumulate on the surface of the copper foil, which usually occurs on copper foil thinner than 3/4 ounce weight specification.

Copper foil manufacturers apply excessive amounts of antioxidants to the surface of copper foil.

The laminate manufacturer changed the resin system, stripping thin, or brushing method.

Due to improper operation, there are many fingerprints or oil stains.

DIP in engine oil during punching, blanking or drilling operations.

Possible solutions:

Before any change in laminate manufacturing, cooperate with the laminate manufacturer and specify the user's test items.

It is recommended that laminate manufacturers use fabric like films or other demoulding materials.

Contact the laminate manufacturer to inspect each batch of copper foil that is unqualified; Ask for solutions for removing the resin.

Obtain the removal method from the laminate PCB manufacturer. It is generally recommended to use hydrochloric acid and then remove it by mechanical brushing.

Contact the laminate manufacturer to use mechanical or chEMIcal elimination methods.

Educate personnel in all processes to wear gloves and hold copper clad laminate. Make sure whether the laminate is properly padded or put into a bag during transportation, and whether the padding has low sulfur content and the packaging bag is free of dirt. Make sure that no one touches the copper foil while using the detergent containing silicone.

All laminates shall be degreased before plating or graphic transfer process.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱