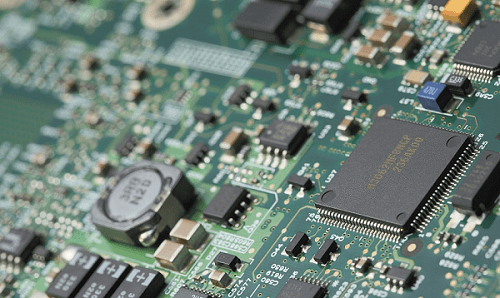

SMT management How to manage SMT pipeline

Management is the planning, organization and control of the daily production activities of the PCB factory. It is the general term of all management work related to product production and an important part of Pcb factory management.

1. PCB production management process organization

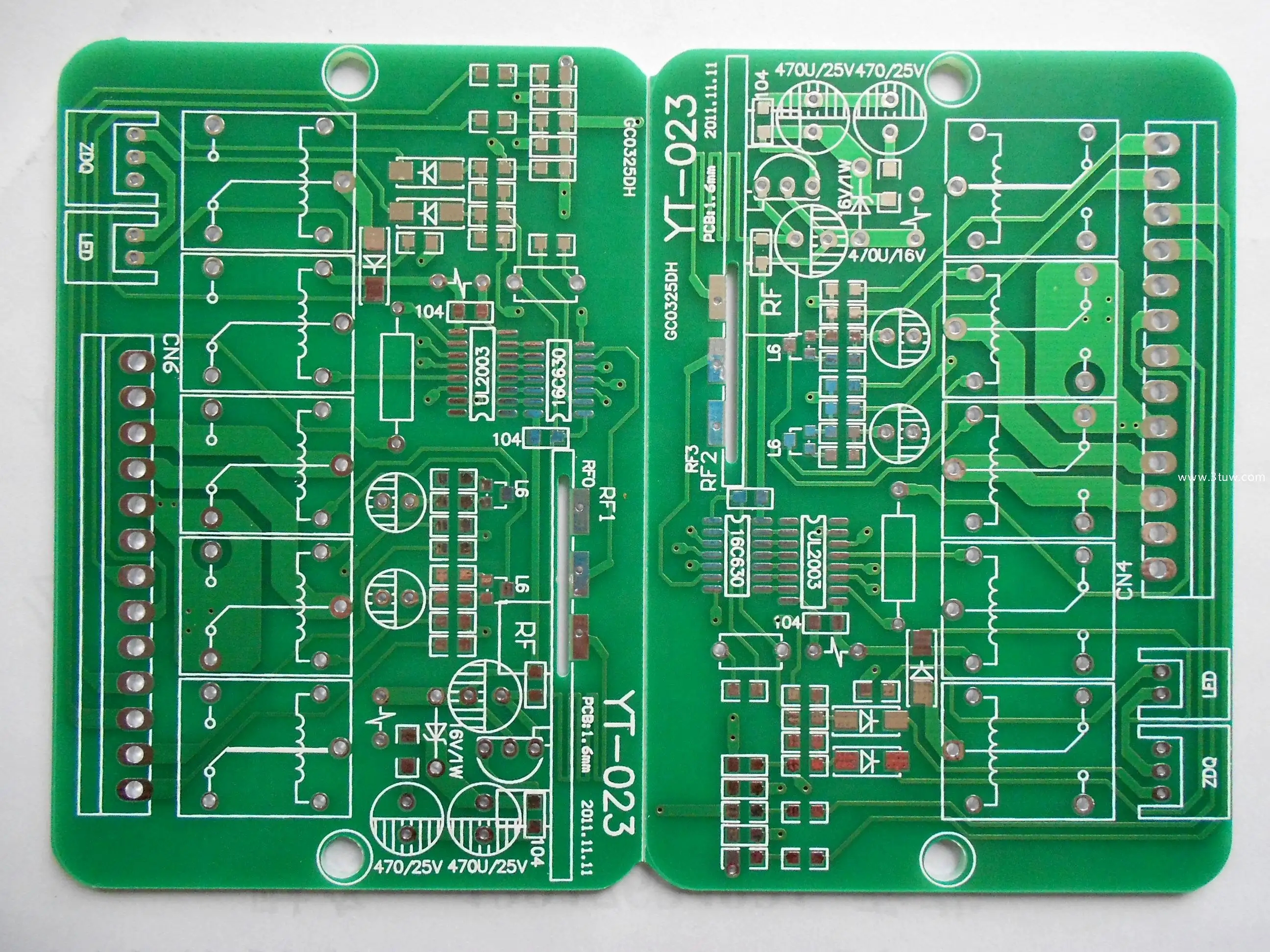

(1) PCB consists of production technology preparation process, basIC production process, auxiliary production process and production service process.

(2) Production process organization The production process shall be continuous, parallel (parallel operation of each stage and process), coordinated and rhythmic (balanced) to ensure economy. The purpose of production process organization is to reasonably and scientifically arrange production, avoid waste of manpower and material resources (equipment), improve labor productivity, shorten production cycle, reduce costs, reduce capital occupation, and complete the plan on schedule, with quality and quantity guaranteed.

2. Preparation of production operation plan The production operation plan of a workshop is an important tool to organize balanced production, complete production tasks and guide production activities in the workshop. Its work contents include:

(1) Formulate advanced and reasonable quality standards.

(2) Formulate monthly production operation plans for teams and workplaces.

(3) Calculate and balance the internal production capacity of the workshop.

(4) Control of production operation plan, including production scheduling, progress management, WIP management, operation accounting, production operation statistics and analysis.

(5) Put forward the plan of production technology organization measures.

3. Workshop production control Workshop production control refers to the supervision, inspection, adjustment and correction of the implementation of the operation plan in the workshop production process. The main work of workshop production control includes production scheduling, job accounting and job analysis.

(1) Production scheduling Production scheduling is the work of checking, supervising and assisting the production input and production progress of each link in production according to the requirements of the workshop operation plan. Scheduling is the key to completing the workshop operation plan. The dispatching work shall have sound systems, including duty system, reporting system, meeting system, on-site dispatching system, etc.

(2) Activity accounting includes the output and input of products and parts (production period and input period), completion schedule, work tasks completed in each link, utilization rate of production workers and equipment, etc.

(3) Job analysis Job analysis is the work after the requirements, records and accounting of production control, summarizing and analyzing the completion of indicators, and giving information feedback, so that it can be used as the basis for production activities and scheduling.

4. Application of group technology Group technology, also calLED group technology (GT for short), is a method based on the principle of SIMilarity to reasonably organize pcb production technology preparation and product production process. Group technology is to classify and code all parts in the workshop according to the classification system of geometric shape (shaft, disk, box, gear, etc.), size, processing method (turning, milling, planing, grinding, pliers, etc.), accuracy requirements (ordinary, precision, high precision), and blank type (bar, plate, tube, casting, forging, etc.), and divide part groups, so as to prepare for production and organize production. The production organization forms of group technology include:

(1) The group process center organizes some parts with similar structure to be processed uniformly on a certain equipment.

(2) A group production unit organizes one or more groups of parts with similar processes to provide a unified process route and arrange equipment.

(3) Group assembly line Group assembly line is used to process group production units with flow production characteristics in sequence, and the processing time of each operation is equal to the flow rhythm, which is used for batch production.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱