How much do you know about PCB surface treatment process

Although at present, the change in PCB surface treatment process is not very big, whICh seems to be a relatively remote matter, it should be noted that long-term slow changes will lead to huge changes With the increasing demand for environmental protection, the surface treatment process of PCB will change dramatically in the future

The basic purpose of surface treatment is to ensure good weldability or electrical efficiency. Since natural copper often exists in the air in the form of oxide, it is unlikely to maintain the original copper state for a long time, so it is necessary to conduct other treatment for copper. Although the strong flux can be used to remove most of the copper oxides in subsequent assembly, it is not easy to remove the strong flux itself. In general, the industry does not use strong flux.

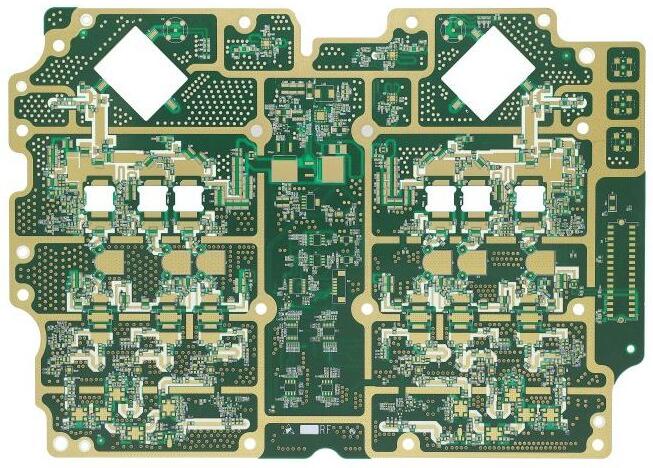

There are many PCB surface treatment processes, including hot air leveling, organic coating, chEMIcal nickel plating/gold immersion, silver immersion and tin immersion, which will be introduced one by one below.

Organic Solderability Preservative (OSP)

OSP is a surface treatment process for printed circuit board (PCB) OSP is the abbreviation of organic solderable preservative, which is translated into Chinese as organic solderable preservative, also known as copper protector, or English notice In short, OSP is an organic film chemically grown on the clean bare copper surface

The film has the effect of oxidation resistance, thermal shock resistance and moisture resistance to protect the copper surface from rust (oxidation or vulcanization, etc.) under normal environment; However, in the subsequent high-temperature welding, this protective film must be easily removed by the flux, so that the exposed clean copper surface can be immediately combined with the molten solder to form a solid solder joint in a very short time.

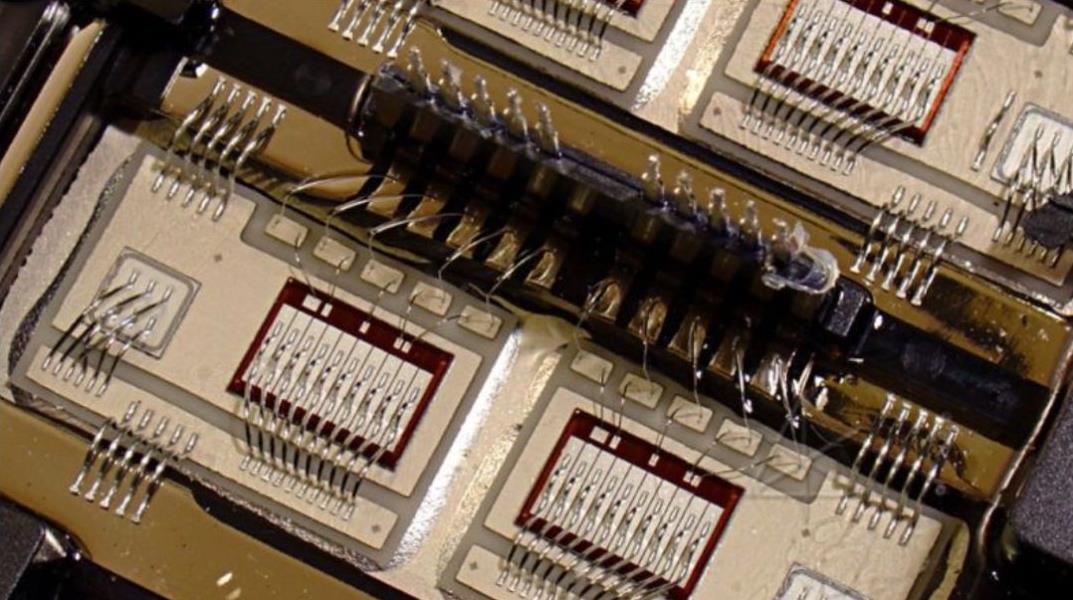

Circuit board

2. Hot air leveling (tin spraying)

Hot air leveling, also known as hot air solder leveling (commonly referred to as tin spraying), is a process in which molten tin (lead) solder is coated on the PCB surface and leveLED (blown) with heated compressed air to form a layer of copper oxidation resistance. It can also provide a coating with good weldability. In the process of hot air leveling, copper tin intermetallic compound is formed at the joint between solder and copper. When PCB is leveled with hot air, it must be immersed in molten solder; Before the solder is solidified, the air knife blows the liquid solder; The air knife can minimize the meniscus of solder on the copper surface and prevent solder bridging.

3. The whole plate is plated with nickel and gold

The nickel gold plating of the board is to first plate a layer of nickel on the PCB surface, and then a layer of gold. Nickel plating is mainly used to prevent diffusion between gold and copper. There are two types of nickel gold plating: soft gold plating (pure gold, the gold surface looks dull) and hard gold plating (the surface is smooth and hard, wear-resistant, containing cobalt and other elements, the gold surface looks brighter). Soft gold is mainly used for gold wire in wafer packaging process; Hard metal is mainly used for power interconnection in non welding areas.

Since all current solders are tin based, this tin layer can match any type of solder. The flat Cu Sn intermetallic compound can be formed during tin deposition. This feature makes tin sinking have the same good solderability as hot air leveling, without the troublesome flatness problem of hot air leveling; The tin plate cannot be stored for too long, and must be assembled in the order of tin deposition.

5. Immersion silver

This immersion silver process is between organic coating and electroless nickel plating/immersion gold The PCB process is relatively SIMple and fast; Even if exposed to high temperature, humidity and pollution, silver can still maintain good solderability, but it will lose luster Immersed silver is no nickel under the silver layer

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱