Key points of pre fabrICation engineering design of multilayer circuit boards

Pre fabrication engineering design of a multilayer circuit board

After the product design and circuit design of the electronic equipment are completed, the parts manufacturing, PCBA board assembly and connection and other steps will be carried out. After testing and confirming the functions, the overall electronic equipment manufacturing will be completed. When designing the circuit board, the designed electronIC components will be configured in the desired area in CAD, and then the component telecommunications transmission planning will be carried out, and then the manufacturing data and test specification documents required for the circuit board manufacturing will be produced for the manufacturers of each section to follow

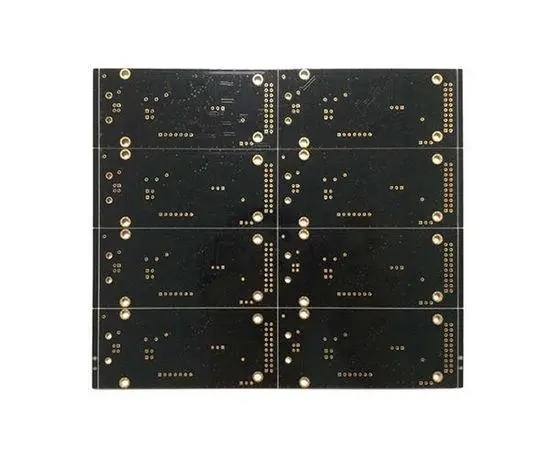

The industrial attribute of PCB processing is mostly OEM, that is, the manufacture of bare boards entrusted by customers. Of course, some companies will have their own Turn Keya54 businesses, such as circuit board design, blank board manufacturing and assembly, even in the same product manufacturing company, but the overall proportion is still SMAll. In the early stage of circuit board production, as long as the original materials provided by the customer, such as Drawing, Artwork, Specification, etc., are manually flipped, typeset, taped, etc., they can be produced. However, in recent years, due to the increasingly thin and short electronic products, PCB manufacturing faces several challenges, such as thin plate, high density, high performance, high speed, shortened product cycle, cost pressure, and precision.

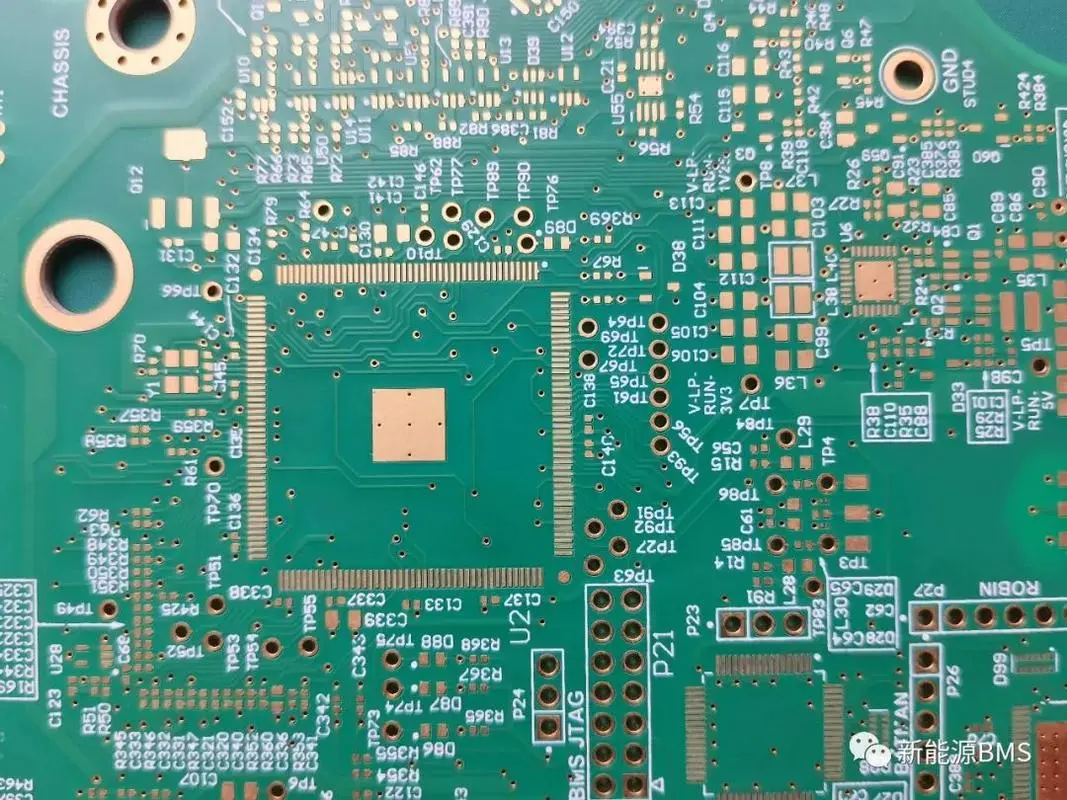

In the past, the lamp table, penknife, map and CAMera were used as pre production tools, but now they have been replaced by computers, working software and laser plotters. In the past, manual typesetting or micro modifier m was required to correct the size and other time-consuming operations. Today, as long as CAM (Computer Aided Manufacturing) personnel obtain customer design data, they may be able to automatically typesetting according to design rules and change different production conditions within a few hours. The DFM (Design For Manufacturing ^ 56 system can SIMultaneously output data such as drilling, forming, testing fixture, etc.

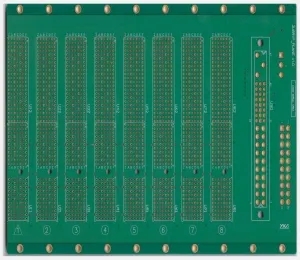

The scope of consideration of pre manufacturing engineering design shall cover different requirements such as component information, assembly mode, material selection, wiring rules, manufacturing procedures, etc., due to the trend of light, thin, short, small, high functionality and action. In the expectation of improving the degree of freedom of design, multilayer circuit board has become a necessary design for most electronic products. With the change of the packaging structure of semiconductor components, in addition to the old through-hole components and DIP, QFP, there are BGA, PGA, CSP, MCM and other diversified matrix packages. After these are considered, all the data are sorted out and filLED into the design drawing of the circuit board to produce various CAM data for circuit board manufacturing.

II. Prerequisite documents for multi-layer circuit board manufacturing

If the circuit board is commissioned to be manufactured by the customer, relevant data as shown in Table 1 must be provided for blank board fabrication. In addition to the necessary items listed in the table, sometiMES the customer will provide a sample, a part drawing, and a guarantee (for example, to ensure that the raw materials and consumables used in the manufacturing process do not contain some toxic substances). The manufacturer must determine the importance of these additional information and use them clearly.

Of course, the manufacturer of the product will have different perceptions of the circuit board used in the product, so he will consider the size, function, power supply mode, heat dissipation method, etc. of the assembly in more detail. If circuit board manufacturers can further participate in the overall function planning, it will be more helpful for product production.

As sEMIconductors become smaller and denser, the energy density of electronic products is bound to increase. Therefore, the design of heat dissipation is the key to the smooth operation of products. At present, the heat dissipation methods of many electronic products have been taken into account in the structural design of circuit boards.

III. Design Content and Data Review

In the face of numerous data provided by customers, the pre production design engineer must review and confirm the data to facilitate the subsequent design and manufacturing. The review focus of general written data.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱