Discussion on Drop Test of PCB Production Line

Generally speaking, in addition to the normal assembly and testing process, the electronIC finished product assembly plant will establish more or less control checkpoints to ensure the quality of its products There are two levels set between product assembly and power test

Knock test

Discussion on Drop Test and Knock Test PCB Production Line

Tap test

The main purpose of knocking is to check whether the finished product has any poor assembly, such as empty solder, false solder, solder balls, solder balls that scratch electronIC parts, and whether the mechanism and screws are assembLED in place.

The impact test stick is usually made by inserting a [bouncing ball] into a wooden stick. When striking, hold the end of the stick and knock the finished product with the elastic ball. It is better to turn on the power when tapping the product. For products with pictures, please pay attention to whether the pictures are abnormal, because some electronic parts with poor welding may have open circuit or short circuit problems only when they are tapped. Usually, the tap test will be placed at the first level of power test, because we do not know whether the product has problems after tapping. If no power test is conducted after tapping, defective products may flow out. In the hands of the customer. The position of detonation is very important, because different positions will have different effects. Knock at the place where the product may produce resonance. The general test shall be repeated for 3 tiMES; It is better to find the most vulnerable part of product design. For a blow, it is invalid if it is only in a hollow area. In addition, the size and weight of the bouncing ball will affect the impact effect, so be careful.

Discussion on Drop Test and Knock Test PCB production Line

Drop test

The drop test here refers to the quality verification of products before delivery, not the drop test of DQ (design quality). The drop test is based on the bare damage of the product. The purpose is the same as the above detonation test. In order to check whether the finished product has any assembly defects, this test and the knock test can complement each other. The key point of the knock test is "resonance", which is repeated 3 times; Fall only once. The fallen desk is made of solid wood, with a layer of 3-5 mm electrostatic table mat on it. When the drop test is conducted, it is free to fall, and it does not need to plug in the power supply or turn on the power supply. As with the knock test, the power test must be carried out after the drop test to ensure that the product has good function and no damage to the appearance. The drop height is usually between 76.2mm (3 inches) and 300mm, which is usually distinguished by the weight of the product. The heavier the weight, the lower the height of descent. The following table is only approximate and for reference, and the actual products of each company shall prevail.

Sheet

Operators on the production line are not afraid of falling products, and the drop test will become lower and lower. In fact, operators should know that the purpose of drop test is to find out the defective products, rather than let the defective products flow into the hands of customers. If the product is returned in the future, it is better to confirm it in the production line. If the product is thrown to the dead place, it should be rewarded. In addition, during the R&D of products, many machines have to fall to more than 76 cm to survive, and they still fall on the concrete floor at four corners of the six sides. Therefore, there is no need to worry that the products will be broken when falling, and the products will fall unexpectedly. On the ground, it damages the appearance.

The above is the explanation given by the editor of PCB circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

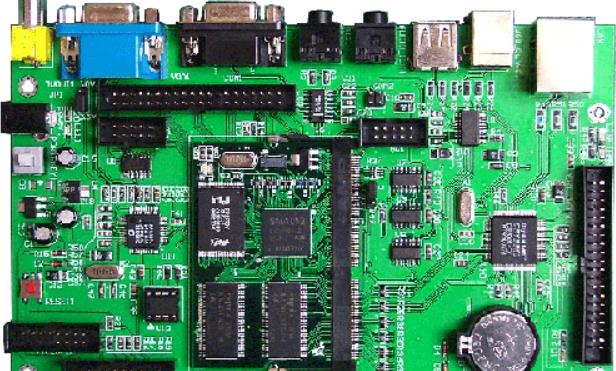

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱