鑫景福致力于滿足“快速服務,零缺陷,輔助研發”PCBA訂購單需求。

PCBA加工

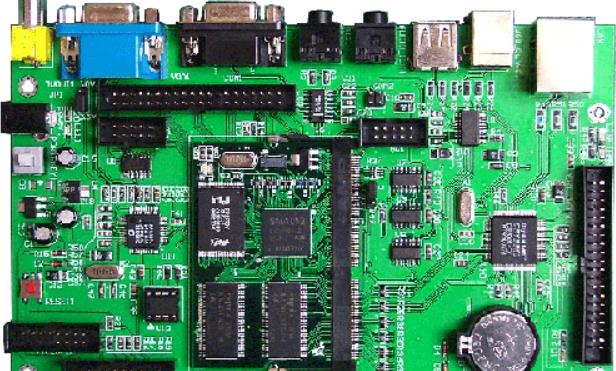

SMT chip for PCB processing of printed circuit board

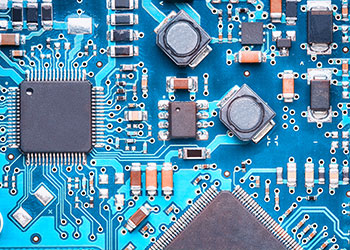

Printed circuit boards are commonly referred to as PCBs Components on PCB are calLED circuit board components or polychlorinated biphenyls The component on the board can be SMT (surface mount) components, plug-in components, pressure components or assemblies In the last artICle, I shared the SMT solder paste printing technology polychlorinated biphenyls (PCB components). Today, I shared the SMT technology and polychlorinated biphenyls

SMT components have many advantages over plug-in components. SMAll size, low height, automatic production, good high-frequency characteristics, low cost. Surface mount components are surface mounted, avoiding the internal PCB traces, and are widely used in some high-end products. SMT components are relatively short, providing competitiveness for many current customers who are pursuing thinner products. In production, the placement machine is used for automatic placement, which greatly improves the production efficiency. Its pin free or short pin design improves the high-frequency characteristics and has good stability. In addition, low cost is also the eternal pursuit of manufacturers.

Example of SMT mounting process

Integrated circuits with various packaging forms have developed from the initial commonly used SOP to QFP, QFN, and then to BGA. The assembly is changed from lead to lead-free, the welding position is changed from two sides to four sides, and then a welding ball is formed at the bottom and top of the assembly. The number of solder joints of SOP components varies from 4 to more than 3000 of BGA components. These changes fully demonstrate the progress of component and PCB manufacturers in the design and production process.

Surface Mount Technology has also changed. First, after printing the solder paste, apply red glue on the PCB, then patch, and finally weld the solder pieces together through wave soldering. So far, it is not necessary to distribute red glue. SMT directly prints solder paste, then installs it, and reflow soldering is enough.

Considering the placement efficiency and quality, large PCBs usually use multiple mounters to complete the placement process The general rule is to use a high-speed chip mounter to paste some chip components, such as such as resistors, capacitors, inductors, etc, And then paste crystals, transistors, light-EMItting diodes, small integrated circuits, etc Some large components, such as BGA type integrated circuits, large connectors, such as memory slots, etc It is arranged in the final multifunctional mounter Number of components selected at one time for the tip mounter nozzle, placement position, etc, Polychlorinated biphenyl components can be designed according to the efficiency and layout of the mounter

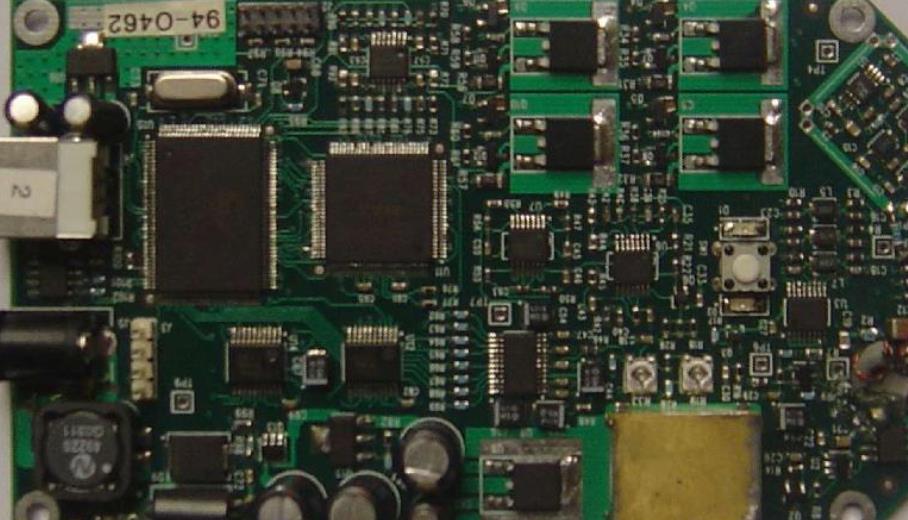

The most common problems in SMT chip production are component inversion, offset, few parts, occasionally damaged parts, multiple parts, etc. In NPI stage of trial production of new products, due to insufficient understanding of the polarity of product components, there may be problems with the batch of polar components, such as diode, LED and IC. These can be found and corrected in FAI. The problem of misalignment can be solved by adjusting the coordinates and height of parts. When the suction nozzle of the mounter is dirty or damaged, resulting in insufficient vacuum, the leakage problem will occur. Components dropped during driving sometimes fall onto PCB board, resulting in various abnormalities at specific positions.

Example of missing part of SMT assembly

Another catastrophic anomaly is a damaged component Even though the factory has many testing and inspection processes, such as AOI, online ICT testing, functional testing BFT, and manual appearance inspection, these processes cannot completely detect damaged parts caused by the placement process MLCC capacitors have some damaged parts that cannot be seen on the surface, and even work normally in a short time Only in the process of slicing experiment or long-term use will abnormalities occur Too high or too low suction nozzle pressure may damage the chip assembly When are SMT components on the same product are supplied by multiple manufacturers

Printed circuit boards are commonly referred to as PCBs Components on PCB are calLED circuit board components or polychlorinated biphenyls The component on the board can be SMT (surface mount) components, plug-in components, pressure components or assemblies In the last artICle, I shared the SMT solder paste printing technology polychlorinated biphenyls (PCB components). Today, I shared the SMT technology and polychlorinated biphenyls

SMT components have many advantages over plug-in components. SMAll size, low height, automatic production, good high-frequency characteristics, low cost. Surface mount components are surface mounted, avoiding the internal PCB traces, and are widely used in some high-end products. SMT components are relatively short, providing competitiveness for many current customers who are pursuing thinner products. In production, the placement machine is used for automatic placement, which greatly improves the production efficiency. Its pin free or short pin design improves the high-frequency characteristics and has good stability. In addition, low cost is also the eternal pursuit of manufacturers.

Example of SMT mounting process

Integrated circuits with various packaging forms have developed from the initial commonly used SOP to QFP, QFN, and then to BGA. The assembly is changed from lead to lead-free, the welding position is changed from two sides to four sides, and then a welding ball is formed at the bottom and top of the assembly. The number of solder joints of SOP components varies from 4 to more than 3000 of BGA components. These changes fully demonstrate the progress of component and PCB manufacturers in the design and production process.

Surface Mount Technology has also changed. First, after printing the solder paste, apply red glue on the PCB, then patch, and finally weld the solder pieces together through wave soldering. So far, it is not necessary to distribute red glue. SMT directly prints solder paste, then installs it, and reflow soldering is enough.

Considering the placement efficiency and quality, large PCBs usually use multiple mounters to complete the placement process The general rule is to use a high-speed chip mounter to paste some chip components, such as such as resistors, capacitors, inductors, etc, And then paste crystals, transistors, light-EMItting diodes, small integrated circuits, etc Some large components, such as BGA type integrated circuits, large connectors, such as memory slots, etc It is arranged in the final multifunctional mounter Number of components selected at one time for the tip mounter nozzle, placement position, etc, Polychlorinated biphenyl components can be designed according to the efficiency and layout of the mounter

The most common problems in SMT chip production are component inversion, offset, few parts, occasionally damaged parts, multiple parts, etc. In NPI stage of trial production of new products, due to insufficient understanding of the polarity of product components, there may be problems with the batch of polar components, such as diode, LED and IC. These can be found and corrected in FAI. The problem of misalignment can be solved by adjusting the coordinates and height of parts. When the suction nozzle of the mounter is dirty or damaged, resulting in insufficient vacuum, the leakage problem will occur. Components dropped during driving sometimes fall onto PCB board, resulting in various abnormalities at specific positions.

Example of missing part of SMT assembly

Another catastrophic anomaly is a damaged component Even though the factory has many testing and inspection processes, such as AOI, online ICT testing, functional testing BFT, and manual appearance inspection, these processes cannot completely detect damaged parts caused by the placement process MLCC capacitors have some damaged parts that cannot be seen on the surface, and even work normally in a short time Only in the process of slicing experiment or long-term use will abnormalities occur Too high or too low suction nozzle pressure may damage the chip assembly When are SMT components on the same product are supplied by multiple manufacturers

點擊

然后

聯系

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱