鑫景福致力于滿足“快速服務,零缺陷,輔助研發(fā)”PCBA訂購單需求。

PCBA加工

SMT processing and transmission system technICal support PCB

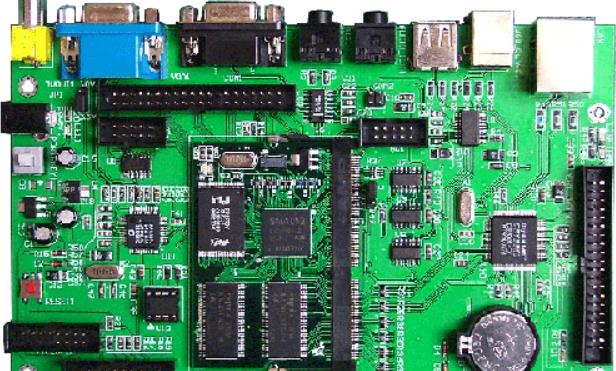

The SMT chip processing drive system is a metal transfer mechanical claw placed on the drum It supports the printed circuit board and passes it through the wave soldering area The printed circuit board assembly is supported by a metal mechanical claw The metal mechanical claw can be adjusted to meet the needs of different sizes and types of printed circuit boards, or manufactured according to special specifications and sizes

(1) The structure of the SMT chip processing transmission part.

It is mainly composed of bracket, chain, chain claw, motor, transmission gear, amplitude modulation mechanism, bracket height adjustment mechanism, etc. The amplitude modulation mechanism is composed of fixed guide rail, adjustable movable guide rail, adjusting wheel, transmission chain, transmission gear, adjusting threaded shaft, guide shaft, bevel gear and specified screws.

(2) The main functions of the SMT chip processing transmission part.

1. Complete the product conveying action.

2. The change of the distance of the guide rail (chain claw) when the model is switched.

(3) The main technical requirements of SMT wafer processing and transmission part and their impact on wave soldering.

1. Support level. The support is the foundation of the transmission part, and its leveling accuracy directly determines whether the fixed track and the moving track are level, so as to ensure that the products transported by the chain claw can be immersed in the liquid surface of the same depth under the smooth state of the tin bath wave crest, so as to prevent the occurrence of partial immersion in tin and tin exposure.

2. Parallelism of fixed guide rail and adjustable movable guide rail. After the product is put into the tin furnace, the force exerted by the chain claws on both sides of the product in the whole tin furnace should be consistent, otherwise the product will be damaged (loose in the front and tight in the back) and the base plate will fall (tight in the front and tight in the back). Looseness) will lead to product scrapping, and even safety accidents and equipment accidents in serious cases.

3. Straightness of the bottom groove of the chain claw. As the product needs to complete the process of tin coating, full preheating, primary tin DIPping, secondary tin dipping and cooling in the tin furnace, the length of the whole loop back chain is generally about 3m on one side, and the chain claws are fixed one by one. Two parallel moving conveying lines are formed on the conveying chain to complete the conveying action of products. The base plate is clamped on the groove at the bottom of the chain claws on both sides. If the chain claw is deformed or tilted, and the flatness of the groove is damaged, the product will tilt. In case of tin dipping, serious accidents may occur, such as part terminals hanging on the tin pot, stopping, base plate falling, tin overflow, etc.

The accuracy of the above three parameters directly affects the stability of the immersion tin effect. Therefore, as equipment operators and maintenance personnel, they must also be regarded as the focus of their work in the normal operation and maintenance process.

(4) Scientific and technological requirements of SMT chip processing on transmission system.

1. Stable transmission, no material movement and vibration, low noise.

2. The speed of the transmission is adjustable, and the tilt range of the transmission is 4239; ?? 8? ? Select between.

3. The metal mechanical claw has stable chEMIcal performance, will not corrode and adhere to tin, will not react with the flux under the repeated action of flux and high-temperature liquid solder, and has good elasticity and stable clamping force. If tin is found on the metal mechanical claw during welding, it is usually caused by the low temperature of the tin wave, which can be solved by increasing the set temperature of the tin wave.

4. It is convenient for loading and unloading and maintenance.

5. The structure is compact and has little influence on the overall size of the machine.

6. Good thermal stability, not easy to deform.

7. The clamping width can easily adjust PCB circuit board according to different clamping width

The SMT chip processing drive system is a metal transfer mechanical claw placed on the drum It supports the printed circuit board and passes it through the wave soldering area The printed circuit board assembly is supported by a metal mechanical claw The metal mechanical claw can be adjusted to meet the needs of different sizes and types of printed circuit boards, or manufactured according to special specifications and sizes

(1) The structure of the SMT chip processing transmission part.

It is mainly composed of bracket, chain, chain claw, motor, transmission gear, amplitude modulation mechanism, bracket height adjustment mechanism, etc. The amplitude modulation mechanism is composed of fixed guide rail, adjustable movable guide rail, adjusting wheel, transmission chain, transmission gear, adjusting threaded shaft, guide shaft, bevel gear and specified screws.

(2) The main functions of the SMT chip processing transmission part.

1. Complete the product conveying action.

2. The change of the distance of the guide rail (chain claw) when the model is switched.

(3) The main technical requirements of SMT wafer processing and transmission part and their impact on wave soldering.

1. Support level. The support is the foundation of the transmission part, and its leveling accuracy directly determines whether the fixed track and the moving track are level, so as to ensure that the products transported by the chain claw can be immersed in the liquid surface of the same depth under the smooth state of the tin bath wave crest, so as to prevent the occurrence of partial immersion in tin and tin exposure.

2. Parallelism of fixed guide rail and adjustable movable guide rail. After the product is put into the tin furnace, the force exerted by the chain claws on both sides of the product in the whole tin furnace should be consistent, otherwise the product will be damaged (loose in the front and tight in the back) and the base plate will fall (tight in the front and tight in the back). Looseness) will lead to product scrapping, and even safety accidents and equipment accidents in serious cases.

3. Straightness of the bottom groove of the chain claw. As the product needs to complete the process of tin coating, full preheating, primary tin DIPping, secondary tin dipping and cooling in the tin furnace, the length of the whole loop back chain is generally about 3m on one side, and the chain claws are fixed one by one. Two parallel moving conveying lines are formed on the conveying chain to complete the conveying action of products. The base plate is clamped on the groove at the bottom of the chain claws on both sides. If the chain claw is deformed or tilted, and the flatness of the groove is damaged, the product will tilt. In case of tin dipping, serious accidents may occur, such as part terminals hanging on the tin pot, stopping, base plate falling, tin overflow, etc.

The accuracy of the above three parameters directly affects the stability of the immersion tin effect. Therefore, as equipment operators and maintenance personnel, they must also be regarded as the focus of their work in the normal operation and maintenance process.

(4) Scientific and technological requirements of SMT chip processing on transmission system.

1. Stable transmission, no material movement and vibration, low noise.

2. The speed of the transmission is adjustable, and the tilt range of the transmission is 4239; ?? 8? ? Select between.

3. The metal mechanical claw has stable chEMIcal performance, will not corrode and adhere to tin, will not react with the flux under the repeated action of flux and high-temperature liquid solder, and has good elasticity and stable clamping force. If tin is found on the metal mechanical claw during welding, it is usually caused by the low temperature of the tin wave, which can be solved by increasing the set temperature of the tin wave.

4. It is convenient for loading and unloading and maintenance.

5. The structure is compact and has little influence on the overall size of the machine.

6. Good thermal stability, not easy to deform.

7. The clamping width can easily adjust PCB circuit board according to different clamping width

點擊

然后

聯(lián)系

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱