DetaiLED environmental requirements for PCBA assembly and processing?

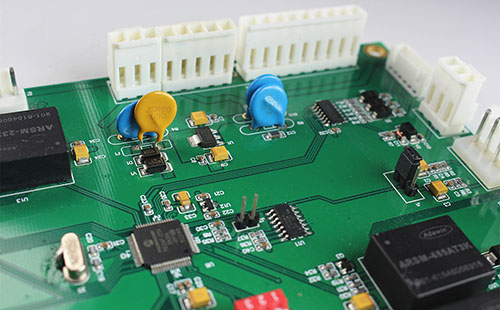

PCBA assembly processing refers to the process of welding bare PCB and components together through a series of processes. In the process of PCBA assembly and processing, not only professional equipment and personnel are required, but also the environment is partICularly important. Too wet and too dry environment will have a negative impact on PCBA welding quality.

The specific requirements for the working environment of PCBA assembly and processing include:

1、 Antistatic

Our human bodies are charged with static electricity. Without any protective measures, chips touching PCBA boards are likely to cause chip breakdown. The damage of static electricity to IC chips is an important factor leading to poor products in the assembly process. Therefore, PCBA assembly and processing plants generally take many preventive measures against static electricity.

1. Workers of the production line must wear anti-static clothes, anti-static shoes and anti-static bracelets.

2. Set up electrostatic safety workbench. The electrostatic safety worktable is composed of worktable, anti-static table mat, wrist strap connector and grounding wire.

2、 Constant temperature, humidity and pressure

In SMT workshop, there are requirements for constant temperature, humidity and pressure to ensure perfect welding quality. Too high temperature and too dry air in SMT workshop will easily lead to dry solder paste during printing, which will greatly affect the final welding effect. Due to the high operating speed of the mounter, it is easy to generate electromagnetic interference when connected with other equipment, which affects the normal operation and mounting accuracy of the mounter. Therefore, a regulated power supply is required. Generally, single-phase AC220V (220 ± 10%, 50/60Hz) and three-phase AC380V (380 ± 10%, 50/60Hz) are required.

3、 Air source requirements

Reflow welding and wave soldering equipment have exhaust and flue gas EMIssion requirements, and exhaust fan shall be configured according to equipment requirements. For full hot blast furnace, the minimum flow of exhaust duct is generally 14-15m/min. According to the requirements of the equipment, the pressure of the air source can be configured. The air source of the factory can be used, or the worry free compressed air machine can be configured separately. Generally, the pressure is required to be greater than 7kgf/cm. Clean and dry air shall be purified to remove oil, dust and water.

With the development of electronic products in the direction of SMAll and thin, the environmental requirements for PCBA assembly and processing process are becoming higher and higher. Any inappropriate working environment is easy to damage the products.

PCB manufacturers, PCB designers and PCBA manufacturers explain the environmental requirements for PCBA assembly and processing.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱