How to prevent false soldering and false soldering in PCBA processing? What are the methods

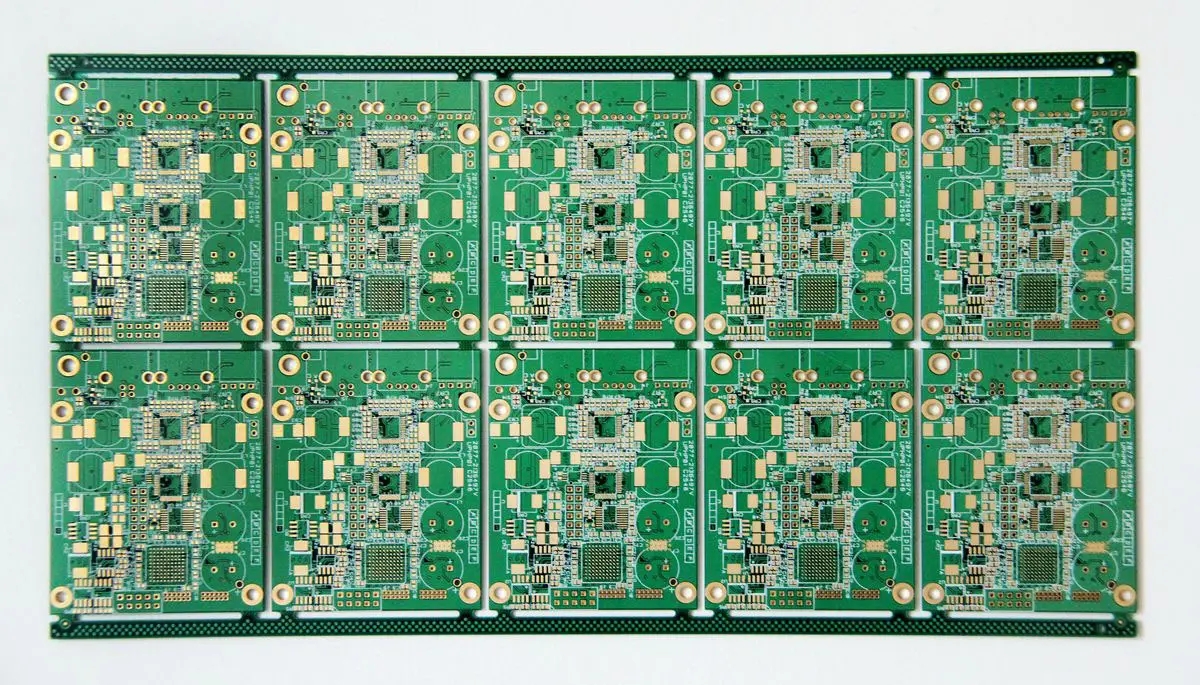

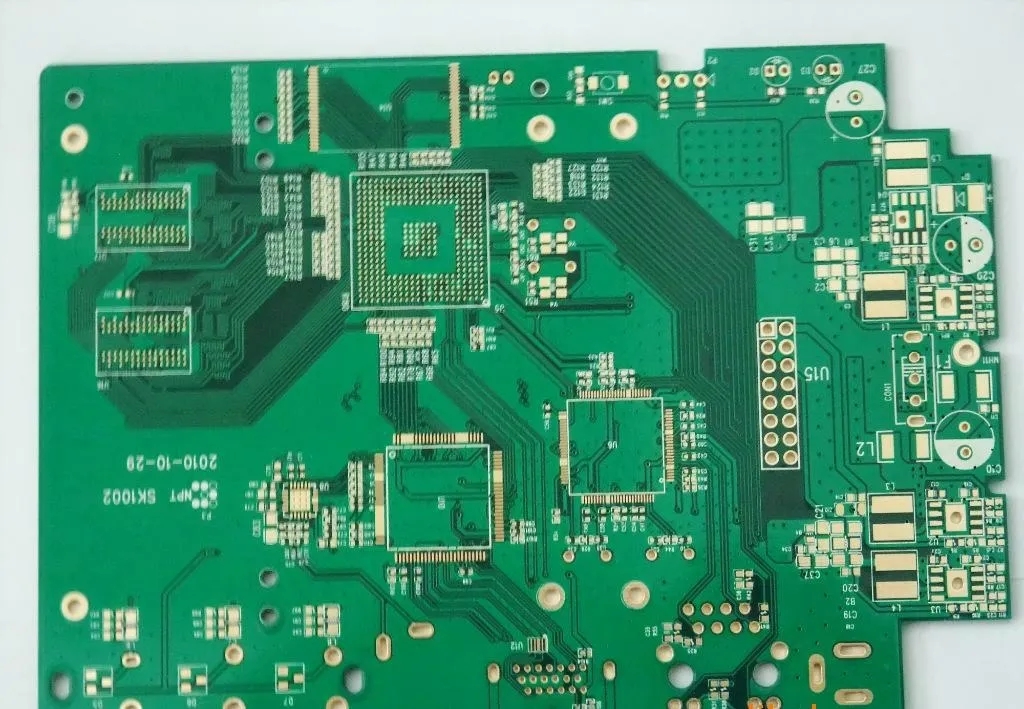

The problem of false soldering and false soldering in PCBA production not only brings great potential quality problems to products, but also has a bad impact on customers, seriously affects the company's image, reduces production effICiency and increases production costs. Next, the following methods and measures will be provided to prevent false soldering and false soldering in PCBA processing.

The problem of false soldering and false soldering in PCBA production not only brings great potential quality problems to products, but also has a bad impact on customers, seriously affects the company's image, reduces production efficiency and increases production costs. Next, the following methods and measures will be provided to prevent false soldering and false soldering in PCBA processing.

Due to the existence of false soldering and false soldering, the reliability of printed boards and the overall product is greatly reduced, unnecessary maintenance is caused in the production process, production costs are increased, production efficiency is reduced, and great quality and safety risks are caused to the products that have already left the factory, and after-sales maintenance costs are increased.

How to prevent false soldering and false soldering in PCBA processing? What are the methods

PCBA problem reduction and preventive measures

1. Important precautions during welding

1.1 Electric soldering iron: whether the soldering iron head is clean, smooth and free of oxidation. If there is an oxide layer, the soldering iron head needs to be wiped clean on the high-temperature sponge before welding; Whether the temperature control of the soldering iron is within the required range or not, too high or too low temperature will cause poor welding. Generally, the temperature is controlLED at 300 ° to 360 °, and the welding time is less than 5 seconds; Different power and types of electric soldering irons shall be selected according to the size of different parts and welding points and the shape of devices.

1.2 Solder wire: high-quality solder wire shall be selected. The amount of solder (63% tin, 37% lead) shall be appropriate. Solder joints shall be subject to wetting the pad with solder, and the vias shall also be wetted and filled.

1.3 Other materials and tools: correctly use the flux, check whether the equipment is normal when using the auxiliary welding equipment, and operate according to the operating instructions and precautions. Maintain the equipment in time after use. (SEMI automatic tin DIPping machine, crimping pliers, etc.)

1.4 Before welding, check whether the device pins are oxidized, and whether the wires, welding pads or transformer pins are oxidized. For oxide devices, the oxide layer should be removed first and then welded to prevent the existence of oxide layer which may lead to false soldering. The welding materials and environment shall be clean to prevent poor welding due to dirt and dust.

2. Strictly implement the relevant process regulations, give full play to the role of self inspection, mutual inspection and quality inspection in the production process, and improve the qualification rate of inspection through some necessary tools and tooling.

3. Relevant departments shall carry out targeted skills and knowledge training to improve employees' own operating skills; Explain the hazards of the above problems to employees, and improve the sense of responsibility of production employees; Take necessary documents to ensure the correctness and reliability of production.

4. The Quality Management Department shall strengthen the inspection of relevant problems and take special reward and punishment measures based on the existing Quality AssesSMEnt System for special and outstanding problems.

In the final analysis, the problem of false welding and false welding in welding is the responsibility and operation skills of employees. Employees should be allowed to truly form a product quality awareness, improve their responsibility and operation skills, improve production from devices, tools, relevant systems and other aspects, and minimize and prevent the occurrence of false welding and other unqualified problems.

The Circuit board manufacturer explains how to prevent false soldering and false soldering during PCBA processing? What are the methods

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱