About SMT Chip Processing Sensor System

Various sensors are instalLED on the SMT placement machine, such as pressure sensor, negative pressure sensor and position sensor These sensors continuously monitor the operation status of the mounter during operation The more sensors are used, the higher the intelligent level of the machine

1) Pressure sensor

The pressure system of the mounting machine includes various air working pressures and vacuum generators. These generators have certain requirements for air pressure. When the pressure is lower than the specified pressure of the equipment, the machine cannot work properly. The pressure sensor always monitors the pressure change. Once the machine is abnormal, it will alarm in time and rEMInd the operator to deal with it in time.

2) Negative pressure sensor

The suction nozzle on the placement head sucks the components through the negative pressure, whICh is composed of a negative pressure generator and a vacuum sensor. When the negative pressure is insufficient, the components will not be sucked in. When the feeder has no parts or the parts are stuck on the feeder and cannot be sucked in, the suction nozzle will not suck in the parts. The occurrence of these conditions will affect the normal operation of the machine. The working negative pressure sensor always monitors the change of negative pressure. When parts cannot be inhaled or cannot be inhaled, an alarm can be given in time to remind the operator to replace the feeder or check whether the suction nozzle and negative pressure hose are blocked.

3) Position sensor

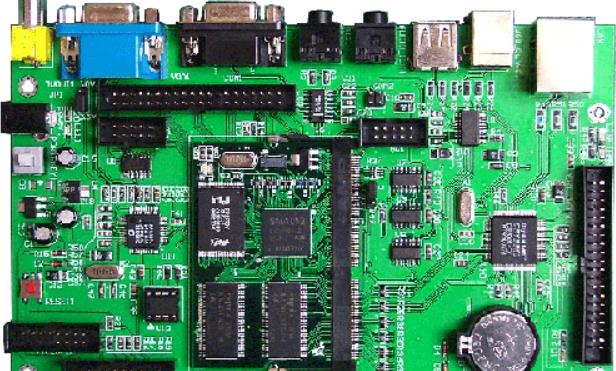

Circuit board

PCB transmission and positioning include PCB counting, placement head and workbench real-time monitoring, auxiliary mechanism movement, etc, All of them have strict requirements for positions and are realized through various forms of position sensors On the front runway, there are usually two sensors The sensor at the PCB inlet mainly detects whether the PCB is imported Once the PCB is detected, the conveyor belt on the front track will run If a PCB is waiting or connected to the middle rail, the entrance PCB moves to the second sensor position of the front rail and stops After waiting for the PCB on the middle track to export, it will be transferred to the middle track for placement If a PCB is waiting at the second sensor position of the front rail, even if the sensor at the PCB inlet detects a PCB, the conveyor belt on the front rail will stop running and be in the waiting state The sensor on the middle track mainly detects whether there is a PCB waiting to be installed If a PCB is detected, the placement program will run quickly and the assembly will be installed in different positions on the PCB according to the instructions After the components on the PCB are assembled, they are quickly led into the rear end track, and the conveyor belt on the rear end track will run to export the instalLED PCB to the next process If the PCB blockage occurs at the outlet of the rear rail, even if the PCB on the middle rail is installed, the PCB will not be exported During the placement process of the placement machine, the placement head moves at high speed along the% axis and the y axis In order to prevent the placement head from hitting the machine arm, there are two restrictions in the X and Y directions of the placement machine Position sensor. Once the placement head reaches the limit sensor, the machine will stop running immediately It can be seen that the limit sensor mainly protects the placement head

LED lighting patch processing 009

4) Image sensor

The real-time display of the working state of the placement machine mainly uses a CCD image sensor, which can collect various required image signals, including the position of PCB and the size of components. Through computer analysis and processing, the placement head can complete the adjustment and placement work.

5) Laser sensor

Laser is now widely used in mounters, which can help determine the coplanarity of device pins. When the device under test runs to the monitoring position of the laser sensor, the laser beam illuminates the IC pin and reflects to the laser reader. If the reflected beam is the same as the transmitted beam, the coplanarity of the device is acceptable; When they are different, the device will cause deformation, which will make the beam emitted longer, and the laser sensor will identify that the device wire is defective. SIMilarly, the laser sensor can also identify the height of the equipment, thus reducing the production preparation time.

6) Area sensor

When the SMT machine is working, for the safe operation of the tip, sensors are usually installed in the moving area of the tip, and the operating space is monitored through the photoelectric principle to prevent foreign material damage.

7) SMD head pressure sensor

With the improvement of placement head speed and accuracy, the requirement of placing components on PCB with placement head becoMES higher and higher This is often referred to as the "z-axis soft landing" function, which uses pressure sensors and servos The load characteristic of the motor is realized When the component is placed on the PCB, it will vibrate at this time, and its vibration force can be transmitted to the control system in time, and then the adjustment echo of the control system will be sent to the placement head, so as to realize the z-axis soft landing function When the placement head with this function works, it feels smooth and light If you further observe, when placing components on the panel, the depth of solder paste immersion in PCB circuit board is roughly the same, to prevent tombstone in the subsequent welding process Welding defects, such as dislocations and fins, are also very beneficial

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱