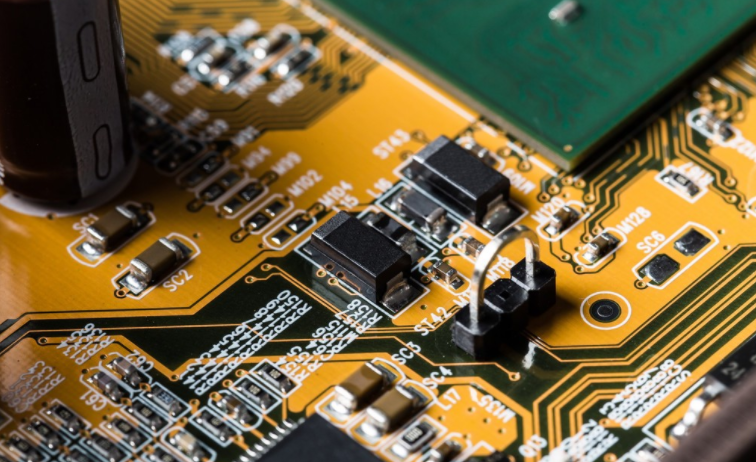

Two Key Points of PCBA Peak Welding Quality Control

pcb assembly manufacturers now have higher and higher requirements for quality in PCB production process welding In terms of quality, PCBs involve plates, and it is important that PCBs begin from the design stage The U.S. Navy found that 40% - 60% of the failures of military electronIC products are caused by design problems Now, the kingford from the polychlorinated biphenyl factory will explain to you the two key points of product quality control. The peak value of polychlorinated biphenyls in the welding process of polychlorinated biphenyls is being processed by the polychlorinated biphenyl technology store

Product development adopts parallel management mechanism. In production practice, welding defects caused by improper PCB design of PCB manufacturers emerge in endlessly. Because of these defects, it is difficult to improve operation and innovate technology alone, which leads to the embarrassing situation of "congenital deficiency, acquired difficulty". Recall that the quality control of PCBs peak welding in SMT technology equipment should start from the design stage of PCBs and let the initial idea run through the whole process before delivery and packaging.

Polychlorinated biphenyls

At the beginning of each new project, PCB design, mutual trust and cooperation mechanism between design, process, production and quality inspectors should be set up That is to say, the only correct way to solve the welding defects caused by the defect design is to carry out the parallel technical route for the early involvement of patch processing, the production and quality inspector in product development Establish a strict management mechanism for solderability of components The weldability of metal surface depends on the removal of dirt and oxide film on the surface and the inherent temperature of the metal Peak soldering practice PCBs in SMT equipment show that maintaining good solderability of electronic component leads is the basis for obtaining good solder joints, and it is also an important measure to obtain the best production efficiency in chip processing plants

It is often found in production that as long as the weldment is well welded on the PCB, even if the welding parameter deviation is large, a good welding effect can be obtained, that is, the sensitivity to the fluctuation of process parameters is very low during chip mounting processing On the contrary, it is very sensitive to the fluctuation of process parameters, the process window is very narrow, the operation is difficult, and the welding quality is unstable Therefore, when purchasing parts, PCB, airport, etc, Considering the technical conditions of component delivery, it is necessary to add solderability and maintain the temperature limit time to ensure the solderability of components

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱