SMT mounting speed of SMT mounting machine and quICk understanding of SMT process flow

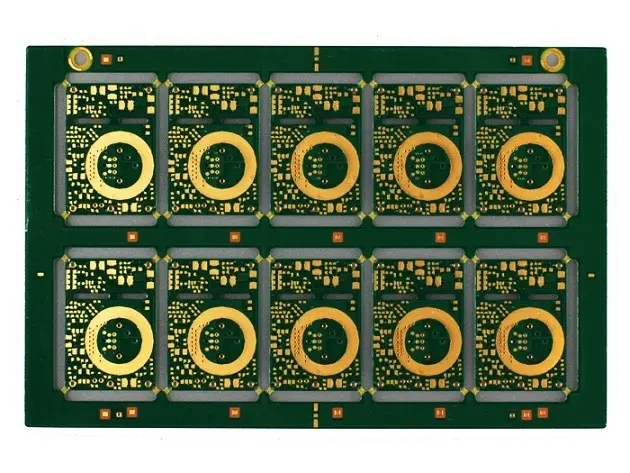

Manual soldering takes 3 seconds to mount a SIMple component. If you mount a complex chip, such as QFP and PLCC chips, it is estimated that it will take half an hour. If you mount a BGA chip, it is estimated that it is difficult to mount a simple component manually. But do you know how many components can be mounted on a high-speed mounter in a second?

The mounting speed of the mounter is so fast, but the mounting accuracy is very high. Few components will be misplaced. That is because the mounter has a high-precision visual positioning system. For example, manual mounting of one million components will generally misplace 10000 components. However, when SMT machine is used to mount one million components, only 60 components will be misplaced, and the high-precision process requires one million components, only 0.002 components will be misplaced.

Quickly understand SMT process flow

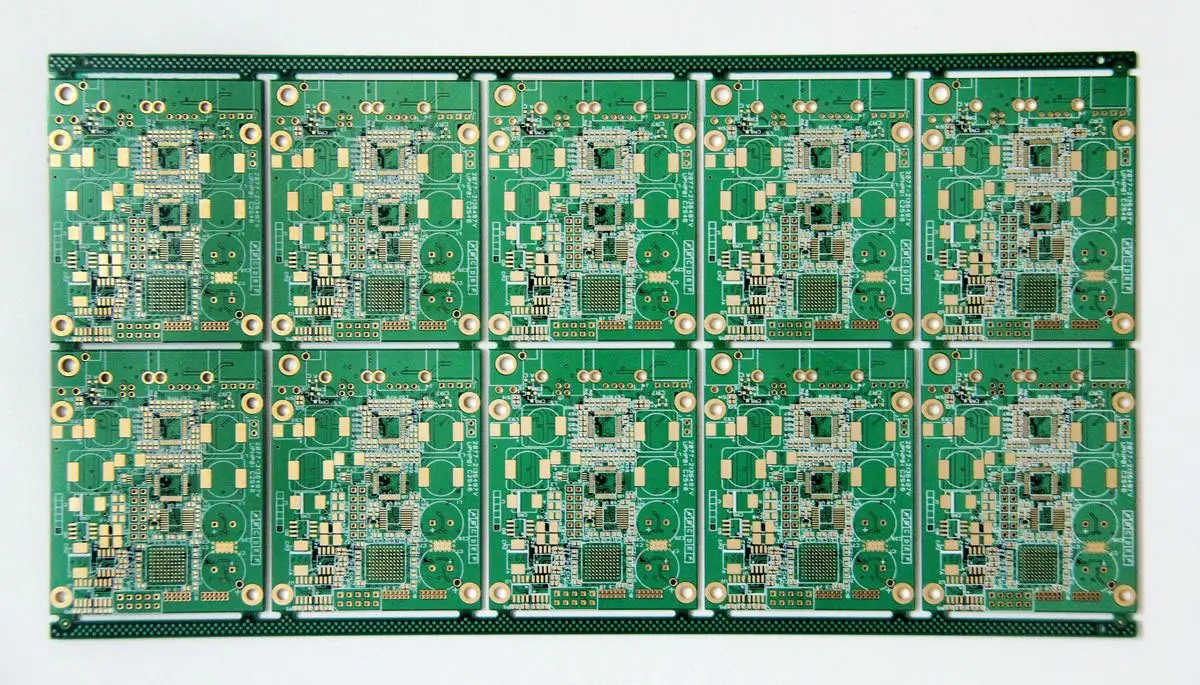

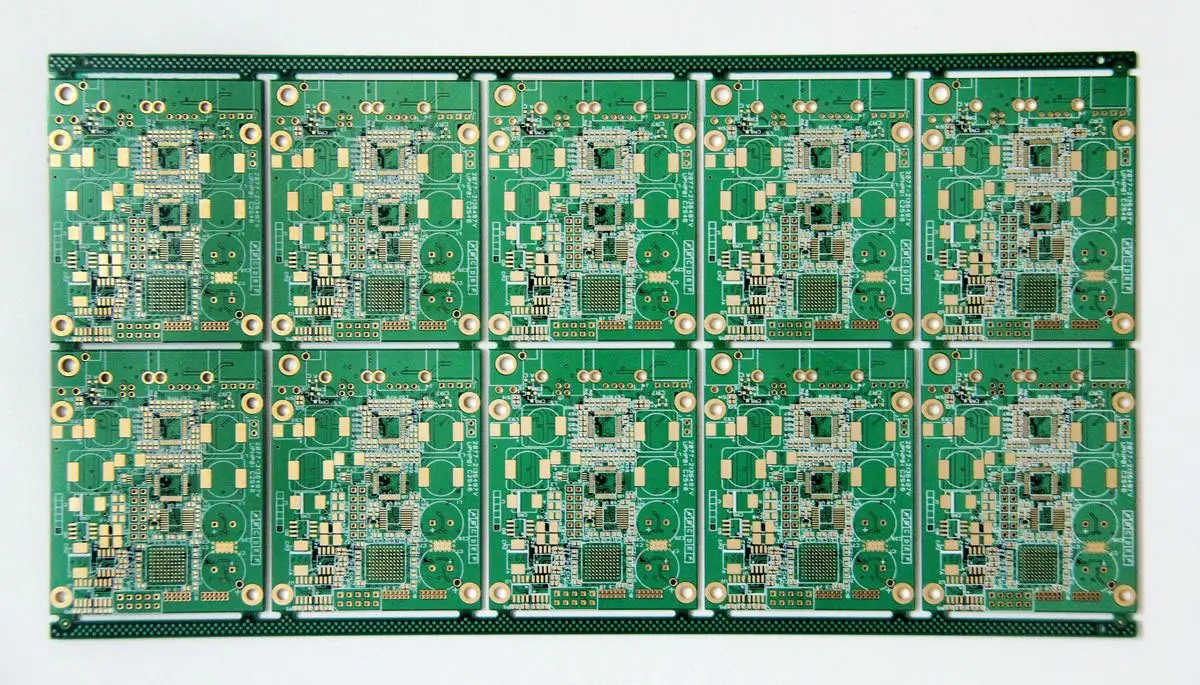

SMT is the most popular technology and process in the electronic assembly industry at present. With the development of electronic products in the direction of SMAller and smaller size, lighter and lighter weight, and stronger functional requirements, SMT process has become more and more complex. SMT process flow can be divided into single-sided assembly, double-sided assembly, single-sided mixed packaging and double-sided mixed packaging according to the assembly mode. (1) Single side assembly process: only surface mounted single side assembly. The process is as follows: printing solder paste=>mounting components=>reflow soldering (2) double-sided assembly process: double-sided assembly with surface mounting only.

SMT is the most popular technology and process in the electronic assembly industry at present. With the development of electronic products in the direction of smaller and smaller size, lighter and lighter weight, and stronger functional requirements, SMT process has become more and more complex.

SMT process flow can be divided into single-sided assembly, double-sided assembly, single-sided mixed packaging and double-sided mixed packaging according to the assembly mode.

(1) Single side assembly process: only surface mounted single side assembly. The process is as follows:

Printing solder paste=>mounting components=>reflow soldering

(2) Double side assembly process: only surface mounted double side assembly. The process is as follows:

Side B printed solder paste=>Side B mounted components=>Side B reflow soldering=>Flip plate=>Side A printed solder paste=>Side A mounted components=>Side A reflow soldering

(3) Single side mixed loading process: THC is on side A, and chip component SMC is on side B. There are generally two kinds of single-sided mixed packaging processes: first pasting and later pasting. The former has low PCB cost and simple process; The latter process is complex.

First pasting method: surface B spot glue=>surface B mounted components=>surface B glue curing=>flip plate=>surface A mounted components=>surface B wave soldering

Post mounting method: Side A plug-in components=>Flip plate=>Side B adhesive point=>Side B mounted components=>Side B adhesive curing=>Side B wave soldering

(4) Double sided mixed packaging process: The double sided process is relatively complex, THC, SMC/SMD may be single sided or double sided.

Procedure 1: A-side printing solder paste=>A-side mounted components=>A-side mounted components=>B-side wave soldering

Procedure 2: A-side printing solder paste=>A-side mounted components=>A-side reflow soldering=>Flip plate=>B-side adhesive point=>B-side mounted components=>B-side adhesive curing=>Flip plate=>A-side plug-in components=>B-side wave soldering

Procedure 3: A-side adhesive spot=>A-side mounted components=>A-side adhesive curing=>flip plate=>B-side printed solder paste=>B-side mounted components=>B-side mounted components=>reflow soldering=>flip plate=>A-side mounted components=>B-side wave soldering

SMT process flow seems to be very complicated. Single side assembly, double side assembly and single side mixed packaging are well understood, but double side mixed packaging is difficult. In fact, it is not complicated to classify them. Double side mixed packaging process 1 is very simple, process 2 is the most commonly used, and the most reliable way. Process 3 is rarely used, and B-side components are required to withstand secondary welding.

According to actual production experience, reflow soldering is generally used for THC components without THC components; For the two with reflow soldering, the reflow soldering of side B is generally carried out first; Both reflow soldering and wave soldering have reflow soldering followed by wave soldering, and wave soldering is generally on side B.

PCB manufacturers, PCB designers and PCBA processors will explain SMT placement speed and quickly understand SMT process flow.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱