DetaiLED introduction to the working principle of SMT mounter

SMT (Surface mount technology), an electronic assembly technology, originated in the 1960s, was initially developed by IBM in the United States, and then gradually matured in the late 1980s. This technology is to install electronIC components, such as resistors, capacitors, transistors, integrated circuits, etc. on printed circuit boards, and form electrICal connections through brazing. The components used are also referred to as SMD (surface mount devices). And plug-in package (through hole technol

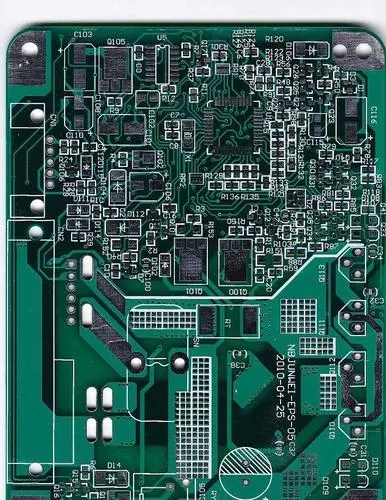

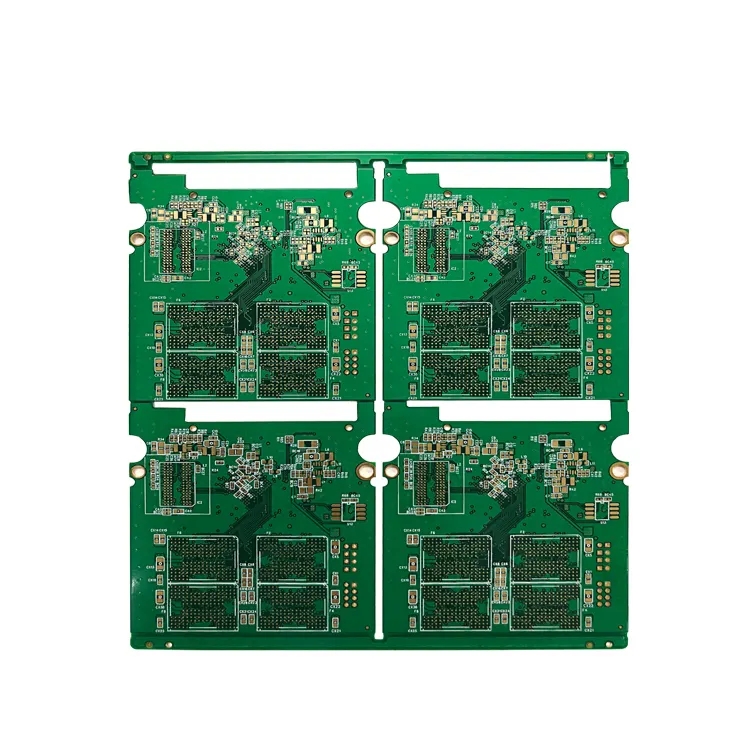

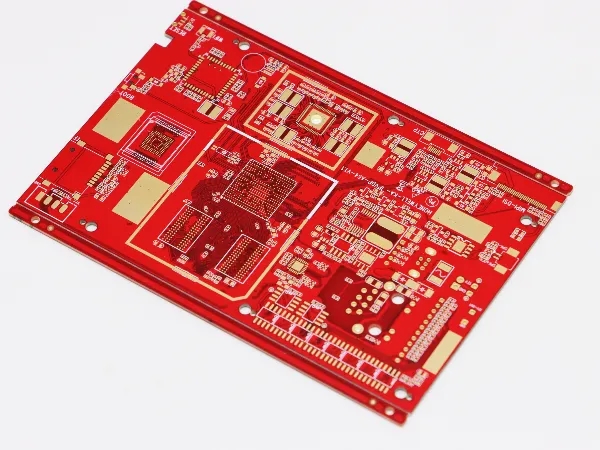

SMT (Surface Mount Technology), an electronic assembly technology, originated in the 1960s, was initially developed by IBM in the United States, and then gradually matured in the late 1980s. This technology is to install electronic components, such as resistors, capacitors, transistors, integrated circuits, etc. on printed circuit boards, and form electrical connections through brazing. The components used are also referred to as SMD (surface mount devices). The biggest difference between SMT and plug-in technology is that SMT does not need to reserve corresponding through holes for the pins of components, and the component size of SMT is much SMAller than that of plug-in packaging.

SMT mounting machine is the main equipment used in SMT manufacturing process, which is used to realize high-speed and high-precision automatic placement of components. It is the most critical and complex equipment in the entire SMT production. At present, with the development of portable and miniaturized electronic products, the corresponding SMC/SMD is also developing towards miniaturization. However, in order to meet the multi-function requirements of IC chips, multi lead and fine pitch are adopted.

SMT mounter is actually a kind of precise industrial robot, which is a combination of mechanical, electrical, optical and computer control technologies. It can quickly and accurately mount SMC/SMD components to the designated pad position of PCB without damaging the components and PCB through the functions of absorption displacement positioning placement. There are three types of element alignment: mechanical alignment, laser alignment and visual alignment. The mounter is composed of a frame, an x-y motion mechanism (ball screw, linear guide rail, drive motor), a mounting head, a component feeder, a PCB bearing mechanism, a component alignment detection device, and a computer control system. The movement of the whole machine is mainly realized by an x-y motion mechanism. The power is transmitted by the ball screw, and the directional motion is realized by a rolling linear guide motion pair. This type of transmission is not only characterized by small motion resistance and compact structure, Moreover, the higher motion accuracy effectively ensures the placement accuracy of each component.

1、 Working principle of mounting machine -- arch type

Working principle of arch mounting machine: first, the component feeder and the base plate are fixed, the tip moves back and forth between the feeder and the base plate, takes the component out of the feeder, then adjusts the component position and direction, and finally places it on the base plate.

The advantages of this type of machine are: SIMple system structure, high precision, suitable for various sizes and shapes of components, even special-shaped components. The feeder can be in the form of ribbon, tube or tray. It is suitable for medium and small batch production, and can also be combined with multiple machines for mass production.

2、 Working principle of mounting machine -- turret type

Working principle of turret type mounting machine: the element feeder is placed on a single coordinate moving hopper, the base plate is placed on a moving workbench of X/Y coordinate system, and the mounting head is installed on a turret. During operation, the hopper moves the element feeder to the reclaiming position, and the vacuum suction nozzle on the mounting head takes the element at the reclaiming position, and rotates to the mounting position via the turret. During the rotation, the element position and direction are adjusted, Place the component on the base plate.

This model is superior in speed and is suitable for mass production, but it can only use ribbon packed components. If it is a tight pin, large integrated circuit, and only pallet packaging, it cannot be completed, so it also depends on the cooperation of other models.

The Circuit board manufacturer, circuit board designer and PCBA processor will explain the working principle of SMT mounter in detail.

The above is the detailed working principle of SMT mounter, for reference only!

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱