Circuit board factory: standard and skill of wave soldering temperature setting

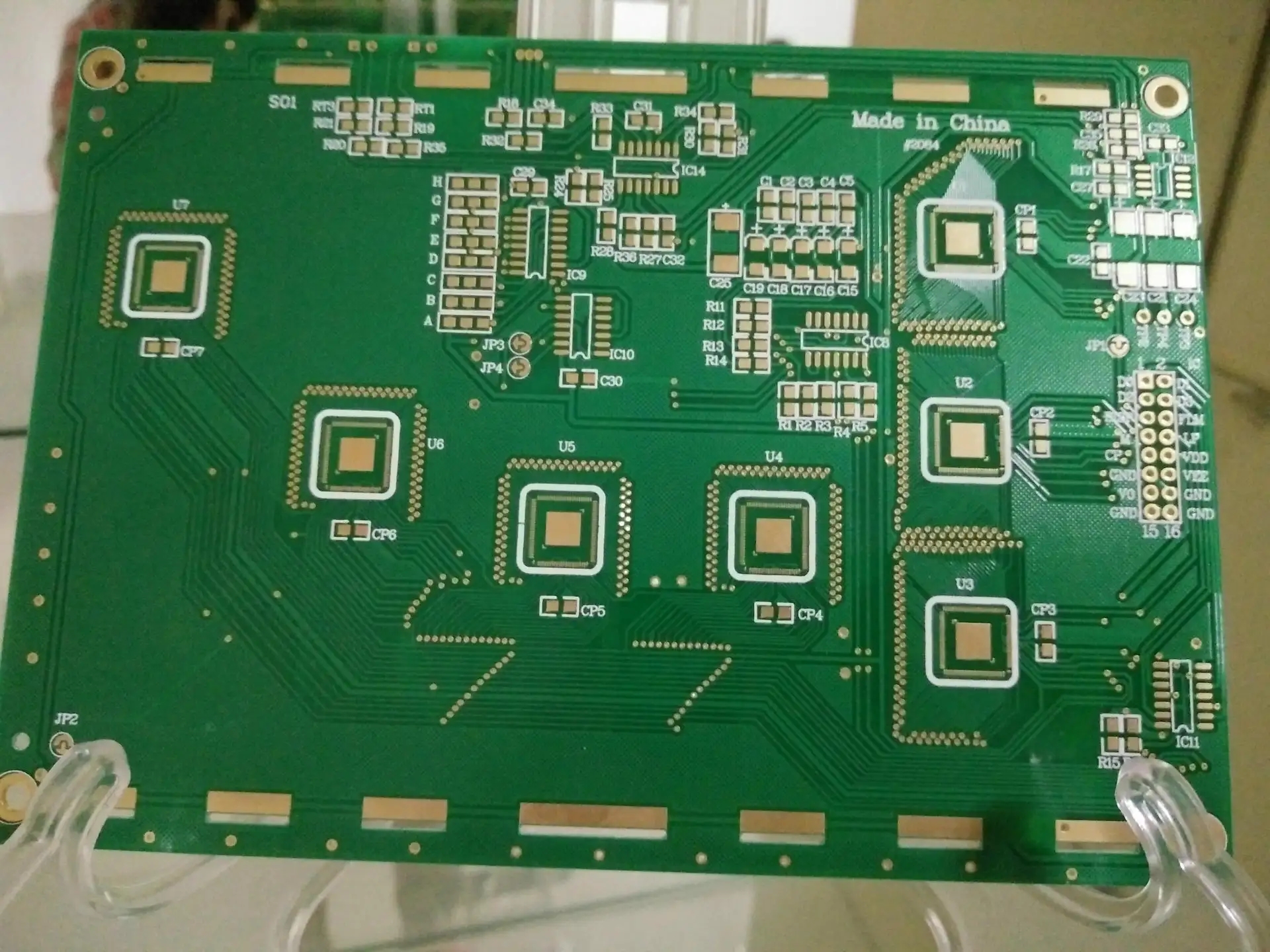

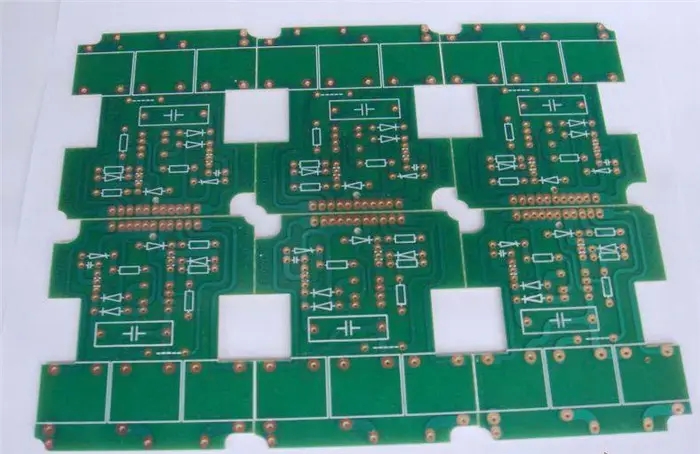

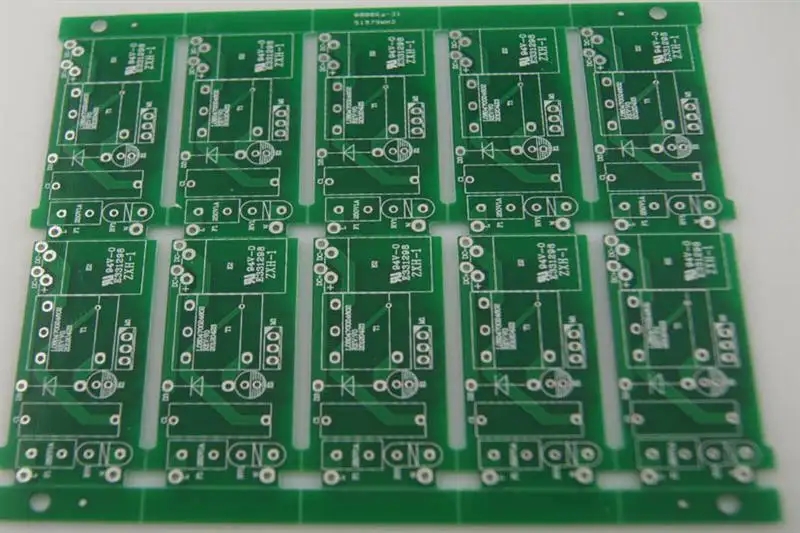

The setting of wave soldering temperature is considered by every electronIC processing factory when processing DIP plug-ins. How should we set it to make the quality of finished products more perfect? The setting of wave soldering temperature is actually the setting of preheating temperature and soldering temperature. The wave soldering processing PCB will pass through the preheating area, welding area and cooling area. Next, the processing experience of our electronic processing wave soldering technicians will provide the wave soldering temperature setting standards and skills, hoping to be helpful to those in need, for reference only! What is the standard for wave soldering temperature setting? The transportation speed is 0.8m/mim

The setting of wave soldering temperature is considered by every electronic processing factory when processing DIP plug-ins. How should we set it to make the quality of finished products more perfect? The setting of wave soldering temperature is actually the setting of preheating temperature and soldering temperature. The wave soldering processing PCB will pass through the preheating area, welding area and cooling area. Next, we summarize the processing experience of wave soldering technicians in electronic processing, and give the setting standards and skills of wave soldering temperature, hoping to help those in need, for reference only!

Standard for wave soldering temperature setting

The transportation speed is 0.8m/mim~1.8m/min;

Preheating temperature: 80 ℃~150 ℃, preheating time: 40S-100S

Tin furnace temperature: 250 ℃~280 ℃. Welding time: 2S-8S

Lead free flux (KH-800 type of Kanghui shall prevail)

Lead free thinner (KHX-800 type of Kanghui shall prevail)

It is abnormal when the actual temperature on the wave soldering display of our company differs from the set temperature by more than 5 ℃ (excluding 5 ℃), and wave soldering cannot be used at this time. (It is abnormal if the difference between the fixture and the set temperature is more than 10 ℃)

If the set important parameters of the wave oven need to be modified, they can only be used after being confirmed and archived by the engineer

Belt angle 30 - 70

The air pressure is set at 4-7kgf/cm2

Pinch angle: 4~6 degrees;

Flux spray pressure: 2~3Psi;

Needle valve pressure: 2~4Psi;

Wave soldering temperature curve

Skill of wave soldering temperature setting

1. Welding temperature

The welding temperature of wave soldering is an important process parameter that affects the welding quality. When the welding temperature is too low, the expansion rate and wettability of the solder become poor. Because the pad or component end can not be fully wetted, defects such as false soldering, tip pulling and bridging will occur; When the welding temperature is too high, the oxidation of bonding pads, component pins and solder is accelerated, which is easy to cause false soldering. The welding temperature shall be controlLED at 250+5 ℃.

2. Preheat temperature

The preheating function is to fully volatilize the solvent in the flux, so as to avoid affecting the wetting of the PCB and the formation of solder joints when the PCB passes through the soldering tin; Make the printed board reach a certain temperature before welding to avoid warping deformation caused by thermal shock. Generally, the preheating temperature is controlled at 180~200 ℃, and the preheating time is 1~3 minutes.

3. Rail inclination

The influence of rail inclination on welding effect is obvious, especially when welding high-density SMT devices. When the inclination angle is too SMAll, bridging is more likely to occur, especially in the shielded area of SMT devices during welding; However, if the inclination angle is too large, although it is conducive to the elimination of bridging, the solder joint has too little tin and is prone to false soldering. Therefore, the rail inclination shall be controlled between 5 ° and 7 °.

4. Crest height

The height of wave crest will change due to the passage of welding working time. Proper correction shall be made in the welding process to ensure the ideal height for welding. The tin pressing depth shall be 1/2 - 1/3 of the PCB thickness

The specific actual parameters can only be measured with a professional furnace temperature curve tester. If the parameter does not meet the welding process, the parameter should be adjusted until the test is conducted and the standard is met.

circuit board manufacturers and circuit board designers will explain the standards and techniques for wave soldering temperature setting.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱