Circuit board factory: usage method and specifICation of solder paste thickness gauge

The detection link plays an important role in SMT production. The detection link can be added to each link in the SMT production line to ensure the quality of each production link. In the printing process, the test results are not only related to the performance of the solder paste thickness gauge, but also related to whether the operator has correctly mastered the use method. It is very necessary to master the correct use method and specification of the solder paste thickness gauge. 1、 Before the test, 1. Check that the computer is well connected with the measuring system and the power supply is connected normally. 2. Turn on the computer host and measuring system. 2、 Test 1. When the operating system starts normally, double-click the desktop ASM icon with the mouse,

The detection link plays an important role in SMT production. The detection link can be added to each link in the SMT production line to ensure the quality of each production link. In the printing process, the test results are not only related to the performance of the solder paste thickness gauge, but also related to whether the operator has correctly mastered the use method. It is very necessary to master the correct use method and specification of the solder paste thickness gauge.

1、 Before testing

1. Check that the computer is well connected with the measuring system and the power supply is connected normally.

2. Turn on the computer host and measuring system.

2、 Testing

1. After the operating system starts normally, double-click the desktop ASM icon with the mouse to start the test program.

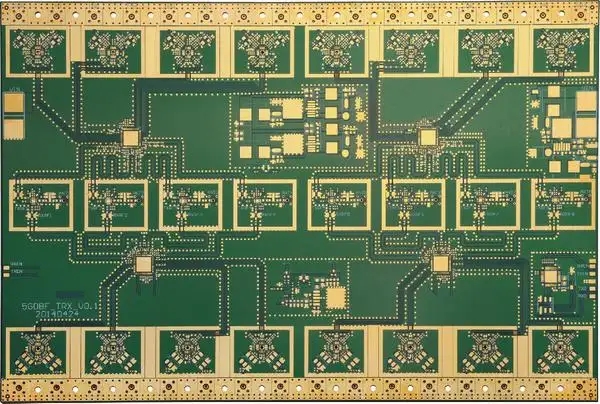

2. Place the PCB board to be tested at an appropriate position on the workbench, find the point to be tested, and adjust the light source and lens to make the image clear. Turn on the laser line and rotate the adjustment mechanism to adjust the overlap between the laser book and the horizontal frame line to reach the appropriate focus.

3. Move the adjusting rod up and down. When the adjusting rod moves to the middle of the reflected light of the laser line, direct measurement can be made.

4. Freeze image [Freeze Image] key, freeze image, image conversion.

5. Window setting/single point measurement setting detection window or click two points with the mouse, and the displacement of two points shall be determined as a point measurement record table.

6. Detection parameter setting T-High/T-Low/SMA/SMD

7. Check Box [Display]

8、Open/Close Image Check Box [Open]/[Close]

9. Thickness calculation T-Low=100~150, T-High=255

10. Area calculation T-Low=100~150, T-High=180~220

11. Display result key/point measurement record table/thickness distribution result

12. Print Results Print/Point Measurement Record Form/Thickness Distribution Results/Image

13. Storage result file → storage point measurement results/working documents/image files

3、 After test

1. End STRONG, close the operation window, exit the control software, and close the computer host.

2. After use, place the mouse and keyboard in the specified position, and keep the table clean and tidy without sundries.

3. Clean the surface of the machine on time to remove dust and other foreign matters.

4、 Precautions

1. Ensure that the voltage supply of the computer host is 220V.

2. The laser light is CALSS Ⅲ pure red light, which is safe for human body, but do not let the light shine for a long time.

3. Non workers are strictly prohibited to operate the machine and do not touch any parts of the machine at will.

4. The computer screen resolution is recommended to be 800X600, 16bit, 85HZ.

The operators of the solder paste thickness gauge should be trained in the use methods and specifications to reduce the errors caused by human factors, improve the accuracy of the detection link, and provide reliable SPC data for the printing process.

The Circuit board manufacturer and circuit board designer will explain the use method and specification of the solder paste thickness gauge.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱