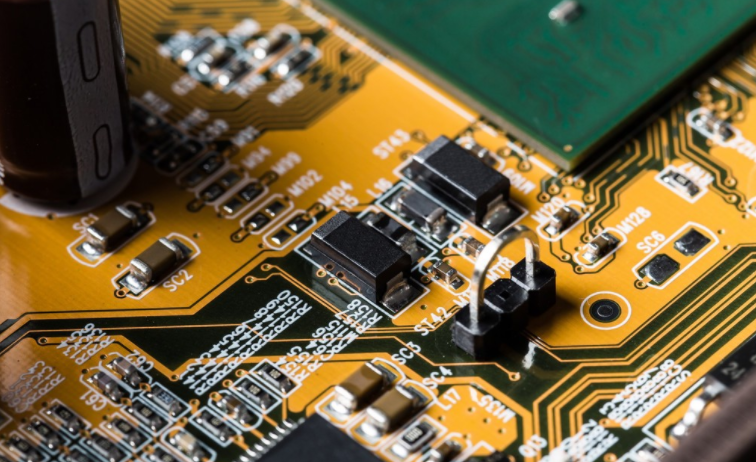

No matter PCB is tested or mass produced, it is necessary to use a sample plate to verify whether PCB productshave problems. In short, it is the trial production before mass production. It is the process that electronIC engineers carry out SMAll batch trial production to the factory after they have designed the circuit and completed the design.

After PCB proofing, SMT mounting is also required to weld the required components to the PCB light board, and then the product function test can be carried out. Then, do you still need to patch the PCB by yourself after proofing?

There are two situations for this problem:

The customer SIMply asked the PCB factory to make a sample, and the board received by the customer was only a smooth board, so the customer needs to find electronIC components for welding after PCB proofing.

When the customer was proofing, he explained that the PCB manufacturer needed to provide SMT mounting service, so after the pcb proofing, the electronic components did not need to be mounted by themselves, and the customer finally received the PCBA circuit board.

Of course, there are some additional costs for manufacturers to provide smt services, including whether they need to purchase electronic components, or whether they need to be provided by customers and welded by PCB manufacturers.

Brief Analysis of Die Cutting Auxiliary Materials Commonly Used in FPC circuit board production

FPC circuit board is also calLED Flexible circuit board, It is referred to as "flexible board", commonly known as FPC in the industry, which is a flexible insulating substrate (mainly polyimide or polyester film) The printed circuit board made of FPC has many advantages that hard printed circuit boards do not have, such as free bending, winding and folding. The volume of electronic products can be greatly reduced by using FPC, which is suitable for the development of electronic products in the direction of high-density, miniaturization and high reliability. Therefore, FPC is used in aerOSPace, military, mobile communication, laptop, computer peripherals, PDA Digital CAMeras and other fields or products have been widely used.

circuit board production

The process of FPC is complex. From material opening and drilling to packaging and shipping, there are more than 20 processes required. In this long production process, according to customer needs, a variety of auxiliary materials will be used. The base material of FPC is generally double-sided or single-sided copper foil, which is the basis of the whole FPC and determines the electrical performance of FPC. Other auxiliary materials are only used to assist installation and adapt to the use environment. They are mainly as follows:

1. FR4 is hard, with different thicknesses of 0.15-2.0mm. It is mainly used on the reverse side of FPC welding as a reinforcement, which is convenient for stable and reliable welding;

FR-4 is a code for the grade of fire-resistant material, which means that the resin material must be able to extinguish itself after burning. It is not a material name, but a material grade. Therefore, there are many kinds of FR-4 materials used for general circuit boards, But most of them are composites made of so-called Tera Function epoxy resin, filler and glass fiber.

2. PI adhesive tape - soft and bendable, mainly used for thickening and strengthening the golden finger area, easy to plug;

PI tape, full name is polyimide tape. PI adhesive tape is based on polyimide film and adopts imported silicone pressure-sensitive adhesive. It has the properties of high and low temperature resistance, acid and alkali resistance, solvent resistance, electrical insulation (Class H), radiation resistance, etc. It is suitable for shielding wave soldering tin of electronic circuit boards, protecting gold finger and high-grade electrical insulation, motor insulation, and fixing positive and negative electrode lugs of lithium batteries.

3. Steel sheet - hard in texture, with the same function as FR4. It is used for reinforcement of welding points. It is more beautiful than FR4 and can be grounded. Its hardness is higher than FR4;

The steel sheet is made of original imported stainless steel after heat treatment and fine grinding. It has the characteristics of high precision, strong tension, good finish, toughness and not easy to break.

4. TPX glue blocking film - a high-performance high temperature resistant resin blocking release film, used in the circuit board pressing process. Through special process design, it can be used in multiple laminating processes to block resin overflowing buried holes and blind through holes, with good glue blocking and hole plugging effects.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱