The production line of PCBA processing plant is composed of many production equipment. The work of each production equipment is different, but the ultimate goal of each equipment is PCB. SMT chip production equipment has the characteristICs of full automation, high precision, high speed, high efficiency, etc. What equipment does a complete and efficient PCBA processing plant mainly include? Generally, the main production equipment of the production line of PCBA processing plant includes solder paste printing machine, dispensing machine, mounting machine, reflow soldering and wave soldering machine, and the auxiliary equipment includes AOI detection equipment, X-RAY equipment, SPI equipment, repair equipment, cleaning equipment, drying equipment, material storage equipment, etc.

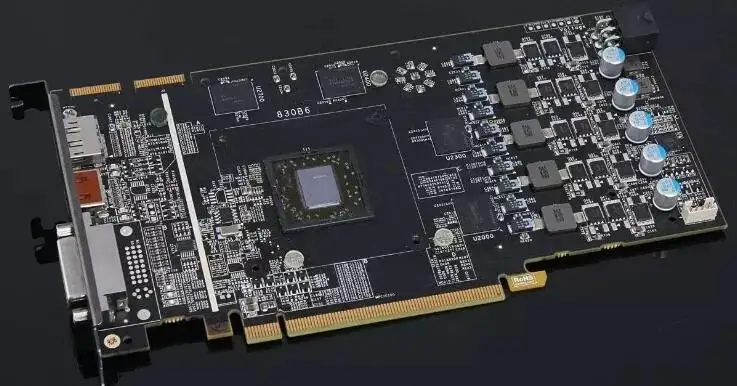

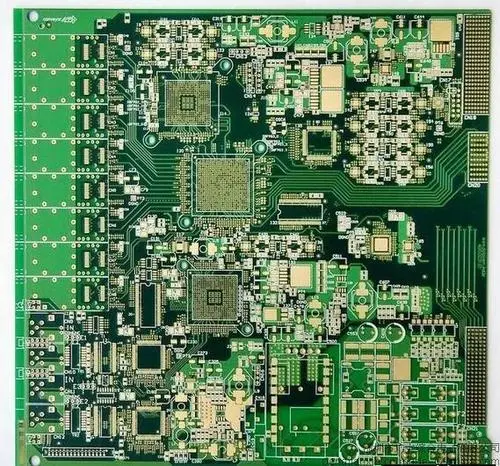

PCBA production

In addition, according to the degree of automation, production scale and production attributes, we can also divide production lines into the following types: according to the degree of automation, they can be divided into fully automatic production lines and sEMI-automatic production lines. Full automatic production line means that the equipment of the whole line is fully automatic equipment, and all production equipment are connected into an automatic line through automatic loading machine, buffer belt and automatic unloading machine. Semi automatic production line means that the main production equipment is not connected or not completely connected, and the printing machine is semi-automatic, requiring manual printing or manual loading and unloading of printed circuit boards.

According to the size of the production line, the production line of printed circuit board can be divided into large, medium and SMAll production lines. Large production lines have large production capacity. The mounter on a large single side production line consists of a universal machine and several high-speed machines. Small and medium-sized production lines are mainly suitable for research institutes and small and medium-sized enterprises, meeting the requirements of multiple varieties, small and medium-sized batches or single varieties. Full automatic production line or semi-automatic production line can be used for medium and small batch production tasks. According to the different categories of production products, the production lines of printed circuit boards can be divided into single production lines and double production lines. The single production line of printed circuit board is composed of automatic surface assembly equipment such as printing machine, mounting machine, reflow furnace, testing equipment, etc. It is mainly used to assemble SMC/SMD products on one side of PCB.

The dual production line of printed circuit board consists of two single production lines of printed circuit board. These two single production lines of printed circuit board can exist independently or in series. They are mainly used to assemble SMC/SMD products on both sides of PCB. When we need or need to find PCBA processing plants, we need to select the appropriate PCBA processing plants according to our actual needs and the positioning of different manufacturers.

1. PCBA production efficiency

When you want a large PCB, many factories may not be able to do it because of their own particularity. Therefore, we need to know whether the supplier can produce and how efficient it is? When the PCB is larger than the industry standard and the supplier does not specifically handle the equipment, the manufacturing speed may be seriously affected. After all, time to MARKet is an important factor in competitive advantage. This may be a big risk item, which will seriously delay the time to market of the product and affect the progress of the entire project.

PCBA production

2. Many layers of circuit board

Although the typical number of layers in a PCB is an even number of layers between 2-10, the number of layers in a large circuit board is much larger. This requires a very professional supplier to complete the work, otherwise the process may be very slow.

3. Cost

In general, because large circuit boards are not suitable for the traditional panel sizes commonly used by suppliers, unit costs will rise.

4. Number of connectors

Generally, large PCBs are mainly used in more complex circuit processing systems. In order to meet more complex functions, a lot of PCB components PCB components and more connectors are needed to achieve them. This means that more technical support, experience and time are needed in chip processing and subsequent assembly testing. This also means spending a lot of time on testing.

然后

聯系

電話熱線

13410863085Q Q

微信

- 郵箱